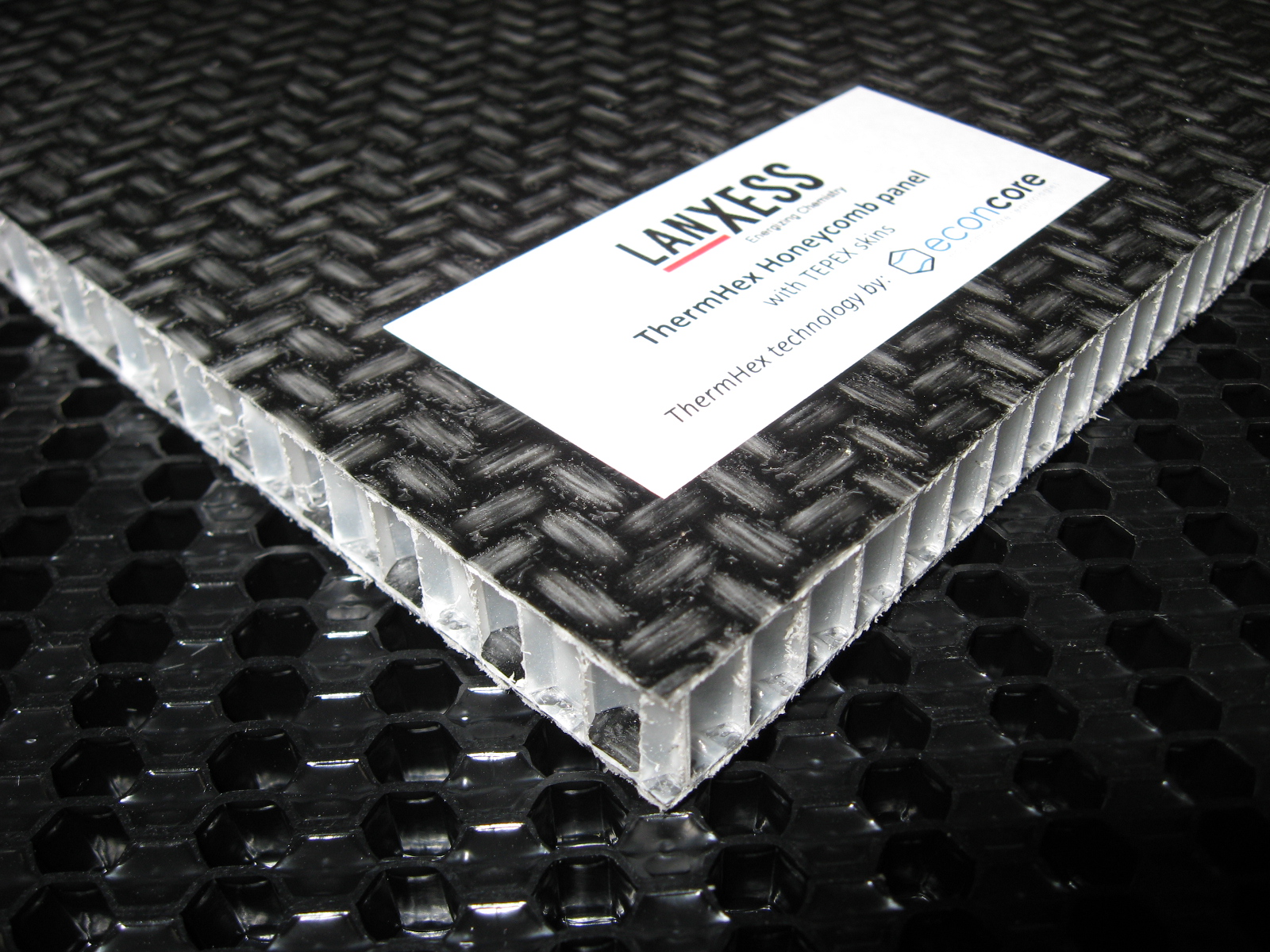

LANXESS and EconCore N.V. are joining forces to develop new thermoplastic sandwich materials for lightweight construction. The objective of the collaboration is to fabricate honeycomb cores from Durethan polyamides with the help of an automated, continuous process patented by EconCore. In addition, Tepex continuous fiber-reinforced thermoplastic composites from LANXESS subsidiary Bond-Laminates are to be combined with the new polyamide honeycomb cores to produce high-performance composites.

Lightweight construction with Tepex

Polyamide honeycomb cores, and the sandwich composites in which they are incorporated, open up entirely new possibilities in lightweight construction, for instance of high load-bearing structural automotive parts. This applies in particular to composites with Tepex facings. “With EconCore and its key technology for the production of lightweight honeycomb cores, we have found a partner who gives us and our customers access to a key method of lightweight construction,” explained Hartwig Meier, head of Product and Applications Development in the LANXESS High Performance Materials business unit. “As a leading global supplier of lightweight construction materials and the associated engineering know-how, LANXESS offers us the great opportunity to develop new mass production applications for our innovative ThermHex honeycomb core technology,” said Jochen Pflug, CEO of EconCore N.V., based in Leuven, Belgium, which operates a German production location, ThermHex Waben GmbH, in Halle (Saale).

Major increase in strength and stiffness

Thanks to their set of properties, high-tech Durethan polyamides lend the honeycomb cores very high stiffness and strength even at relatively high temperatures, and good thermal aging resistance. Combining the honeycomb cores with Tepex facings, for example, results in sandwich composites that raise performance another notch in terms of strength and stiffness. “We expect the thermoplastic sandwich structures, with their high-quality mechanical properties, to be suitable for replacing metal in many areas and thus reducing weight, for instance in motor vehicles, but also in the building and transportation industries, boat and furniture building and motorhome manufacturing,” Meier said.

EconCore is the market leader in technologies for economic honeycomb sandwich production. EconCore’s ThermHex technology allows producing honeycomb cores and sandwich panels in a fast, continuous, in-line process. Due to its high efficiency ThermHex technology is applied typically in mass market applications allowing reductions of product’s cost and weight and consequently reductions of CO2 emissions.

LANXESS is a leading specialty chemicals company with sales of EUR 8.3 billion in 2013 and roughly 17,300 employees in 31 countries. The company is currently represented at 52 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainability indices Dow Jones Sustainability Index (DJSI World and DJSI Europe) and FTSE4Good as well as CDP’s Climate Disclosure Leadership Index (CDLI).