At ITMA Asia, Stäubli will present weaving and knitting solutions. At the event the visitors will learn about weaving preparations and high speed shed formation solutions as well as latest knitting automation device.

Stäubli’s range of products includes:

• shedding solutions for frame weaving

• weaving systems for technical textiles and carpeting

• Deimo automation solutions for sock knitting

• to mastering warp preparation and warp tying, weaving preparation solutions

• in formats for every woven application, electronic Jacquard machines with harnesses

Automated weaving preparation – warp beam preparation

The SAFIR S30 handles filament yarns which features 16 frame/rod capacity that is ideal for high density warps with fine filament yarns. The product range of SAFIR features active warp control, AWC technologies such as double end detection, S/Z yarn management and color repeat. Continuous R&D drives such innovative technologies that deliver advantages to customers.

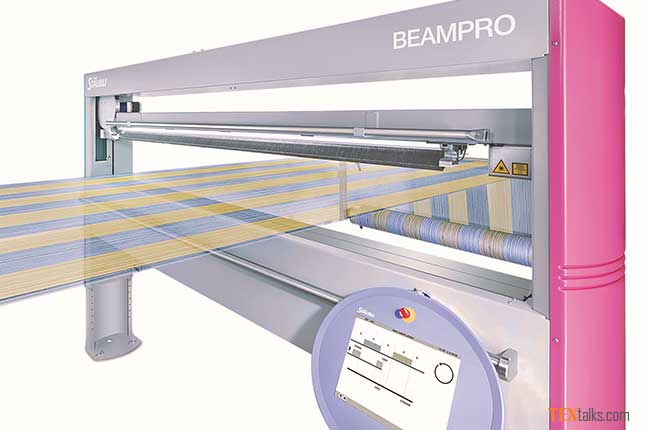

Stäubli’s BEAMPRO yarn repeat reading-in machine is an automation aid for sizing colored warp sheets.

Frame weaving solutions for water-jet applications

Stäubli presented S2658 and S2678 rotary dobbies for water jet applications. In combination with de82/83 har¬ness motions for high mounting, the S2678 will be on display featuring ingenious design incorporating valuable features like maintenance free bearings. These machines are installable on high position on the weaving machines, supporting the production of quality patterned fabrics.

Jacquard weaving – Large format application on display

Jacquard weaving – Large format application on display

Stäubli will showcase jacquard installations featuring several kinds of weft insertion. These installations are equipped with the LX and LXL Jacquard machines, designed for the production of terry and large-format clothing fabrics. Dedicated to large formats, the LXL setup is equipped with 19,584 harness cords (format of the machine exhibited is 10,240 hooks). The display will show the heavy payload capacities of this machine when weaving dense clothing fabrics. The LX setup (format of the machine exhibited is 4,096 hooks) will be shown producing terry fabric, operating 6,652 harness cords with two repeats. A DX Jacquard machine will be shown in an area also demonstrating the broad range of Stäubli harnesses.

Jacquard weaving solutions for name selvedges

The CX 172 and the UNIVALETTE electronic Jacquard machine will be shown. The latter features individual warp-thread control, opening vast possibilities for a wide variety of applications. Both machines allow weavers to apply added value to their woven fabrics.

Carpet samples showing innovative binding technologies

Samples woven on ALPHA carpet weaving systems will be exhibited binding technologies and patterns ranging from extra-high-density carpets with traditional patterns to ultra-modern designer carpets.

Automatic toe-linking device for a shorter sock production process

On two circular knitting machines Stäubli will be showing the recently launched D4S device. This automation solution allows closing the toe of the sock directly on the knitting machine which significantly shortens the sock production process.

Original Stäubli spare parts for extended longevity

Original Stäubli spare parts for extended longevity

Stäubli offers original spare parts even many years after purchase of the machine.