The rapid advance of digital operations technologies and Industry 4.0 solutions represents a great opportunity to increase the competitiveness of manufacturing industry. The increasing connectivity of functions across the value chain (smart factory and operations), smart connected products and data-driven services promise productivity increases of over 20 percent, savings in servicing and maintenance costs of 10 to 40 percent, as well as an increase in “time-to-market” of 20 to 50 percent. In addition, smart connected products serve as a technological foundation for incorporating new business models such as platforms, “as-a-service” models, or data-driven business models and thereby exploit new revenue pools.

There is some level of reluctance in the textile industry to start the digital transformation process. According to a McKinsey study, the hesitation has to do with a number of implementation barriers faced by manufacturers with no/limited progress in Industry 4.0:

• Uncertainties about financial benefits due to a lack of demonstrated business cases justifying investments

• No strategy to coordinate actions across different organizational units

• Missing talent and capabilities, e.g. data scientists

• A lack of courage to push through radical transformation

• Cybersecurity concerns with third-party providers

The Textile Learning Factory 4.0 at the Institut für Textiltechnik der RWTH Aachen University in Aachen, Germany is a world-class training, demonstration and research facility for digital transformation which is opened and is continuously upgraded in collaboration with leading technology and industry partners. The factory is a central location for capability building in a real-life demonstration and learning environment as well as a test base for piloting and scaling-up new digital solutions. There are a broad range of services on offer tailored to the specific needs of company executives, managers, and digital “change agents” in charge of driving the digital transformation process within their companies. The service offering is divided in four main categories:

• Inform about Industry 4.0 and digital transformation topics and how to benefit from the various solutions

• Experience state-of-the-art applications and technologies of leading manufactures and technology providers

• Learn the tools, methods and technologies required to start the digital transformation process

• Kick-start the transformation and generate lasting impact with the support of experienced consultants and the use of the learning factory as an accelerator for building internal capabilities at scale

Based on a standard set of learning modules, workshops and trainings can be tailored to the participants’ individual requirements and needs. Theses workshops and trainings enable anticipation of change required along the three dimensions of a digital transformation:

• The technical system (processes & tools), with a paradigm shift towards smart, connected plants leading to a shift to real-time, data-driven decisions across networks, integrated process optimization, and changes in the physical process execution (e.g., collaborative man-machine interaction, and smart, in-line quality control)

• The management system (organization, IT, performance management), with a need to not only focus on identifying visible waste on the shop floor but also “digital waste” along the end-to-end process

• The people system (capabilities and mindset & behaviors), with significant changes in job profiles across all plant functions, as well as new roles (e.g., data analysts, IT integrators)

The Textile Learning Factory will feature an integrated end-to-end value chain covering Industry 4.0 topics across all operations-related functions and departments and not just focus on manufacturing-related Industry 4.0 solutions. The factory will therefore showcase how a company of the future will operate along its entire value chain.

In order to allow experimental capability building a hands-on realistic factory environment that features an integrated end-to-end value chain for the production of a smart, customizable wristband. The wristband can be individually configured by the participants prior to a training or workshop, and will be produced during the course of the workshop and participants can personalize their own wristbands as well as purchase them from home by using an online product configurator. After the order is placed, the development and adjustment of the product is initiated, followed by production planning and operation scheduling. The next step is the manufacturing of the product from yarn production to final assembly. Manufacturing includes weaving, coating, thermosetting, printing and cutting of the main strap, as well as the final assembly, which includes sewing, testing and packaging of the final product.

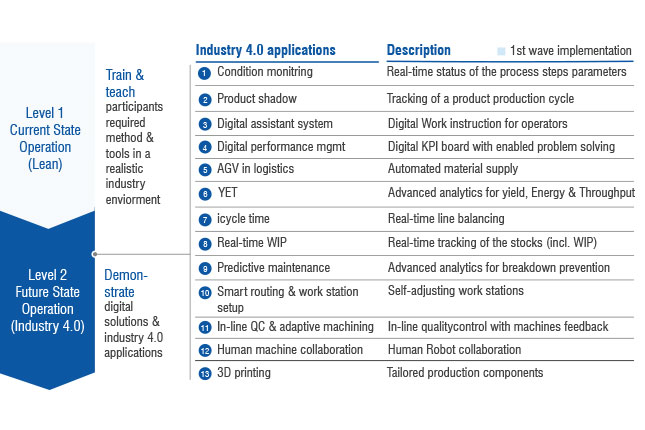

The main aim of the factory environment is to foster hands-on, experimental capability building. Hence, the factory infrastructure needs to meet certain requirements that differentiate it from a real-life factory. One of the key differentiators is the ability to change between two implementation levels of the process:

• Level 1 – Current State Operation (Lean)

• Level 2 – Future State Operation (Industry 4.0)

Level 1 serves as a realistic, good practice industry environment in which main Lean tools and methods such as SMED, value stream mapping, Five S, Kanban (pull systems) and poka-yoke (error-proofing) have been implemented, but the potential of Industry 4.0 applications has not been utilized. Level 1 is used to train and teach participants the required methods and tools to conduct a digital transformation in a realistic factory environment. Level 2 on the other hand is used to showcase the potential of state-of-the-art Industry 4.0 applications directly after the hands-on trainings in Level 1.