A wide range of new technologies will be demonstrated by Vandewiele at the ITMA. All Vandewiele technologies are now being equipped for machine-to-machine interaction and learning, as part of the company’s comprehensive TEXconnect programme.

Van de Wiele provides innovative textile systems for the complete cycle from granulate to carpet, starting with the extrusion and heatsetting of BCF yarns and ending with the weaving or the tufting.

Van de Wiele provides innovative textile systems for the complete cycle from granulate to carpet, starting with the extrusion and heatsetting of BCF yarns and ending with the weaving or the tufting.

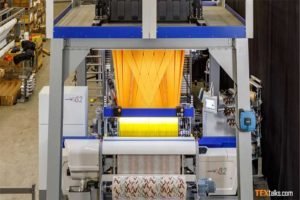

RCE2+ CARPET WEAVING

The new RCE2+ Rug and Carpet Expert weaving machine is a truly digital workhorse, with all yarns continuously controlled and measured and the difficult bobbin changes of the past completely eliminated. This is a result of VAN DE WIELE’s latest Fast Creel, with individual tension control by torque motors on each pile yarn.

The pile yarns are now fed directly into the machine without having to pass pile-stop motions, to both increase efficiency and eliminate any waste yarns, while achieving previously unreachable industrial speeds.

The filling enters the machine smoothly via the latest IRO X3 winders, heavy duty filling brakes with multi lamellas, an active yarn recuperator and a high speed weft mixer, where again, all tensions are set electronically. Vandewiele’s servo-driven heddle frames (Smart Frames) are meanwhile already well proven in the industry.

TEXCONNECT

TEXconnect further provides readily-available data on all yarn consumption, tension and threading, and then will supply the predictive maintenance that is paving the way to self-learning carpet weaving machines.

All of this would be unnecessary, if it didn’t result in allowing manufacturers to make the highest quality carpets at the most economic prices ever, with savings on the highest-bulk pile yarns from the Vandewiele extrusion lines, reduced waste yarns in the creel and industrial production speeds that have never before been attained.

COLORTEC L+

The Cobble COLORTEC L+, which is now the most versatile tufting machine available on the market. By combining the advanced technologies of Individually Controlled Needle (ICN), Individual Pile Delivery (IPD) and Level Cut/Loop (LCL) in one machine, the COLORTEC L+ makes it possible for tufters to produce multi-color jacquard –type cut & loop carpets, for wall-to-wall, area rugs, bathmats, …etc

TITAN 5540

the completely revised Titan 5540 carpet finishing machine from Vandewiele Titan, is now able to finish carpets with straight corners, next to carpets with round corners and complex shapes. The optional integrated label printer allows for traceability throughout your production process of each carpet individually. The fully electrified carpet handling system further improves the stability of the process. The newly designed construction allows for improved ergonomics for the operator.

VSI32 Jacquard

The new VSi32 Velvet Smart Innovator Jacquard, imagine you combine the possiblities of a flat woven Jacquard fabric with pile yarn. A whole new range of fabrics for home and fashion can be created. This is what Van de Wiele shows on the Velvet Smart Innovator VSi32 for Italian velvet.

The Velvet Smart Innovator VSi32 is a digital machine full of servo-controlled motions. However, the big breakthrough in velvet weaving is the Smart Creel for velvet. The long experience of Smart Creels in Axminster weaving has now been introduced in velvet weaving. Moreover, complicated creel set-ups with planted colours become easy. A whole range of new designs are within reach.

Record-Breaking weaving technology from Bonas

Jacquard design from 1,920 up to 31,104 hooks on a single machine. Bonas will reinforce its position as the leading supplier of shedding systems to both the flat weaving and carpet weaving industries worldwide. A total of ten jacquards will be operating on advanced weaving machines throughout the show, six of them in operation at the main Vandewiele stand A206 in Hall 4.

Weft insertion systems

IRO-ROJ continues to expand our weft insertion technology with the introduction of the latest in weft control, whether this is to ensure zero twist, or to automatically guarantee consistent yarn tension.

KNITTING

Control of MEMMINGER-IRO Knitting machine peripherie by CAN BUS capable machines. In order to meet future requirements and industry 4.0 requirements, MEMMINGER-IRO GmbH consistently integrates powerful CAN-BUS systems into its products.

Control of MEMMINGER-IRO Knitting machine peripherie by CAN BUS capable machines. In order to meet future requirements and industry 4.0 requirements, MEMMINGER-IRO GmbH consistently integrates powerful CAN-BUS systems into its products.

This approach enables new product applications as well as more productive working methods and ideally takes place in a complete system integration of the machine control. Quality is assured thanks to the PROTECHNA Laserstop and Needle Sensor. The ARRAYCAM 5420 optical inspection system is suitable for monitoring standard fabrics on all common Tricot warp knitting machines. It impresses with its high quality and an outstanding price-performance ratio.