The Italian textile machinery manufacturer Savio can be defined a denim specialist, providing winding machines that can easily process special and challenging yarns, such as Lycra® and Dual Core Yarns. Savio winding unit is equipped with the Savio winding unit is equipped with clearing, splicing and tension control devices for ensuring perfect splices and perfect package shape.

The demand for denim yarns with elastomeric core is expanding, and plays an important role because of fashion versatility and flexibility. Stretch garments are playing an important role inside this scenario, denim jeans and leggings are highly requested, especially for womenswear. Keeping up this trend of stretch denim, many yarn & fabric manufacturers are offering duo core yarns with improved recovery and strength, while retaining the comfort of cotton next to the skin. Dual core spun yarns are consisting of three components: a core filament – mainly Lycra®, a polyester multifilament as T-400® and a staple fiber- mainly cotton.

The demand for denim yarns with elastomeric core is expanding, and plays an important role because of fashion versatility and flexibility. Stretch garments are playing an important role inside this scenario, denim jeans and leggings are highly requested, especially for womenswear. Keeping up this trend of stretch denim, many yarn & fabric manufacturers are offering duo core yarns with improved recovery and strength, while retaining the comfort of cotton next to the skin. Dual core spun yarns are consisting of three components: a core filament – mainly Lycra®, a polyester multifilament as T-400® and a staple fiber- mainly cotton.

This special yarn offers improved recovery and strength compared to traditional core spun technology. Savio winding machine can easily process special and challenging yarns. Savio winding unit is equipped with splicing and tension control devices for ensuring perfect joints and perfect package shape. A common problem faced by the stretch fabric manufacturers is the breakage of the yarns during downstream process.

This special yarn offers improved recovery and strength compared to traditional core spun technology. Savio winding machine can easily process special and challenging yarns. Savio winding unit is equipped with splicing and tension control devices for ensuring perfect joints and perfect package shape. A common problem faced by the stretch fabric manufacturers is the breakage of the yarns during downstream process.

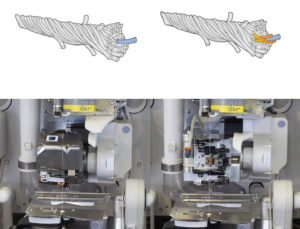

The well-known Savio Twinsplicer® still represents the solution to achieve the best performance of a “perfect joint” on Core Yarns, mainly “single core” with cotton, but also positive results have been achieved with Dual Core Yarns. In this field, Savio can also offer the new splicing technology combining air and water, Moistair®, which represents the most flexible solution of any kind of yarn.

To allow the warping process to be best achieved, winding machines produce big cylindrical packages, usually 300mm in diameter and over, with high density. The peculiar robustness and strength of denim is given by the thickness of the yarn.

Twinsplicer®: the unique selling proposition of Savio

Twinsplicer® is the unique, original and reliable solution to process blends with elastomeric filament. Savio patented it in 1983, a mechanical splicer composed by discs coated with a polymer.

The way the splice is prepared and made, ranks the Twinsplicer® at the top among all other splicing devices. The Twinsplicer® enhances its technological versatility with stretch and spandex yarns (cotton / Lycra®), creating invisible joints with perfect tightness and with the elastic filament core perfectly integrated into the joint. The result of this conception is the Twinfil®, a yarn without knots, perfectly reconstructed at the junction point; this quality comes from a series of fundamental mechanisms that implement and monitor all phases of operation without the use of compressed air and water, recreating the original structure of the yarn.

The Savio Twinsplicer® performs controlled mechanical splice in each phase. The splice is not recognizable from the rest of the yarn and each splice is identical to the other ones. The excellent aesthetic qualities and strength of the splice have a highly positive influence on subsequent processing phases: high warping speed, high-speed waving with automatic weft insertion and knitting. So much so, that nowadays many knitters and even more weavers don’t simply request Twinfil® yarn spliced with Twinsplicer®, they demand it as essential to the quality and final look of their fabrics.

Advantages of Twin Splicer

• The yarn strength near then spliced area is equal or more than parent yarn.

• Warping and weft performance will improve due better splice strength.

• With Core Spun Yarns (CSY), the core filament is incorporated in every joint hence the dyed fabric will not

have any patch mark on the spliced portion and even elasticity is retained in the joint.

• Best choice for denim yarn to fine count core spun yarns with cotton fibers.

• Completely mechanically operated hence no need of compressed air and water. Overall air consumption is reduced by at least 50% compared to air splicing.

• The joint is virtually invisible.

• Reduced setting complexity