![]() Mimaki Europe announced a brand-new large format inkjet printer series, the 330 Series, including the JV330-160, CJV330-160 and TS330-1600, as well as a new range of CG-AR cutting plotters. Launched during the company’s Global Innovation Days event, the 330 Series leverages Mimaki’s cross-platform strategy, to offer a high-end yet cost effective printing solution across several sectors.

Mimaki Europe announced a brand-new large format inkjet printer series, the 330 Series, including the JV330-160, CJV330-160 and TS330-1600, as well as a new range of CG-AR cutting plotters. Launched during the company’s Global Innovation Days event, the 330 Series leverages Mimaki’s cross-platform strategy, to offer a high-end yet cost effective printing solution across several sectors.

Following on from the success of the 100 and 300 Plus Series, the 330 Series was developed to offer mid- to high-end printing models, focusing on high image quality and productivity.

As a company renowned for its high-colour range, Mimaki’s newest printers can achieve high resolution, durable prints for both the Sign Graphic and Textile industries.

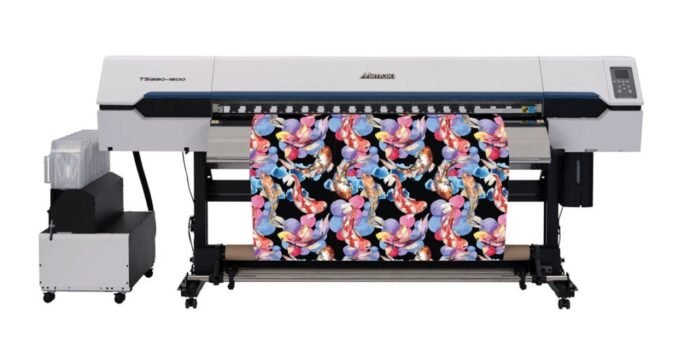

Mimaki has released the TS330-1600, a sublimation transfer inkjet printer, for the textile industry.

Enabling both high production and high image quality, and equipped with new functions to improve stable operation, the TS330-1600 can achieve a printing speed of 69m2/h in Draft mode with a 4-colour ink set, with the fastest mode reaching up to 135m2/h.

The newest cleaning mechanism applies a cloth wiper that removes unwanted ink from the nozzle surface, reducing ink splatter and improving the overall upkeep of the machine.

The TS330-1600, also has optional add-ons to further increase efficiency, including the “10kg ink tank supply unit”, which reduces cost per cc compared to the standard 2L ink pack and allows for longer continuous printing. A mini jumbo roll unit can also be added to load long transfer paper and further reduce running costs.

An improved take-up system featuring dual motors equipped on both sides of the printer distributes the load and strengthens the winding power allowing stable winding of printed paper even for long runs. TxLink4, Mimaki’s RIP software dedicated to the textile market is included with every TS330-1600.

An improved take-up system featuring dual motors equipped on both sides of the printer distributes the load and strengthens the winding power allowing stable winding of printed paper even for long runs. TxLink4, Mimaki’s RIP software dedicated to the textile market is included with every TS330-1600.

All products in the series are fitted with ‘Mimaki Weaving Dot Technology’ (MWDT), a technology that changes the order of ink droplet placement depending on the printing conditions – avoiding streaks or uneven printing due to print head or adjustment issues. ‘Mimaki Remote Access’ (MRA) is also available across the series, improving ease of use, by allowing users to remotely access the machine and check the operation status.