At the DTG Exhibition on 15 – 18 February in Dhaka, Saurer, the premier solution provider for spinning and twisting machines, presents their spinning & twisting machines in hall 7, booth 272. Saurer’s spinning and twisting machines are renowned for their energy-saving features, automation, and digitalization solutions. Saurer machines enable the circular economy in textiles and are the leaders in processing recycled textile materials. Saurer’s Texparts product line offers high-quality components for spinning.

Saurer enables spinning mills to process a wide range of recycled and regenerated fibres and yarns in their production. The Saurer rotor spinning machines are leaders in the processing of recycled fibres. The Saurer textile technology experts continuously assist customers in optimizing their yarn production and yarn quality, especially for recycled fibres. Saurer always been committed to advancing the textile industry, integrating high-end equipment manufacturing with modern information technology to provide sophisticated solutions for the smart spinning factory.

Excellent sliver quality with Saurer’s blow room and carding machines

The right combination of Saurer’s blow room and carding machinery ensures excellent fibre utilization and sliver quality, thus increasing the efficiency of the spinning process and improving the quality of yarn. The new Autocard was developed to create further value in the fibre preparation chain.

The benchmark for intelligent roving and ring spinning

The use of the Autospeed roving frame with automatic doffer ensures that spinning mills do not have to rely on skilled workers, and simultaneously increases the quality of the roving. The Autospeed roving frame with up to 240 spindles saves up to 20% of energy compared with the previous model, while doffing takes less than 2 minutes.

The ZR 72XL and ZI 72XL are two highly productive ring and compact-spinning machines. They set the global benchmarks for intelligent spinning, low energy consumption, user friendliness, and flexible automation solutions.

Saurer – the market leader in rotor spinning

Saurer – the market leader in rotor spinning

The BD 7 semi-automated rotor spinning machine is powered by the technologies of Autocoro. With the patented digital piecing technology, DigiPiecing, and take-up speeds of up to 230 m/min, the BD 7 remarkably improves yarn quality and productivity for spinning mills.

The Autocoro is the market and technology leader which revolutionised automatic rotor-spinning technology and opened the door to more productivity, flexibility, and sustainability for customers worldwide. In just 10 years, Saurer installed 1 million Autocoro spinning positions with individual drive technology and energy saving features.

Autoairo – the new air-spinning technology

The Autoairo sets new benchmarks for air spinning. Saurer combined its most advanced automation solutions with proven technology to create an air-spinning machine with unique properties. The Autoairo features autonomous spinning positions with automation per spinning unit for more productivity and integrated intelligence.

Texparts components for boosted ring spinning productivity

Saurer’s Texparts product line offers high quality components for the textile industry including drafting systems and spindles, spinning rings, and travelers. The new double elastic spindle, Eshape, has a reduced wharf diameter and is based on CS 1 S. Outstanding running properties up to 30 000 rpm and about 6% energy savings are the key performance factors. Eshape, combined with the best system for spinning without underwinding, Spinnfinity, is the perfect fit for automated and efficient ring spinning.

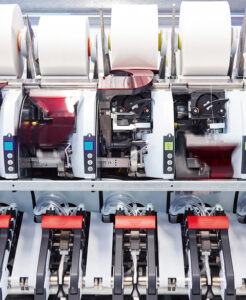

The FusionTwister – two-for-one twisting at the highest speeds

Often used for high-quality towels and bed lining, the two-for-one twisting machine FusionTwister, offers high efficiency combined with the excellent quality of the cross-wound delivery packages produced. Up to 15% of energy can be saved with the FusionTwister while increasing the winding speed by 10%. Consistent high yarn and package quality is a result of the robust machine construction and optimized yarn guiding elements, which consist of yarn-friendly ceramics or plasma-coated surfaces for low friction and longevity.