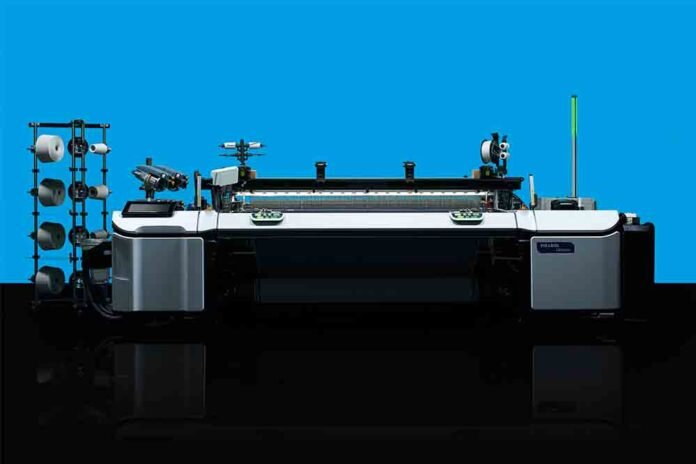

At ITMA 2023, Picanol, the world’s leading weaving machine manufacturer, will be presenting its latest high-tech weaving machines and services at Booth B201 in Hall 6. ITMA is the world’s most influential textile and garment technology exhibition and it takes place from June 8 – 14, 2023, in Milan (Italy). The eye-catcher at the Picanol booth will be the world premiere of an all-new and revolutionary rapier weaving machine, the Ultimax, that will become available in the first quarter of 2024. In total, Picanol will have 12 machines on display at ITMA 2023. In addition to 6 rapier weaving machines, Picanol will also present 4 airjet weaving machines featuring new developments. Furthermore, a rapier machine in Jacquard execution will be on display at the Bonas booth and an airjet machine in Jacquard execution will be presented at the Stäubli booth.

Innovations in airjet technology

ITMA 2023 will also be the moment that Picanol launches a speed increase on its airjet platform, the OmniPlus-i Connect. This is another example of how Picanol sets the benchmark in the industry. Also on display for the very first time will be a brand-new leno system, the o-Leno, which combines smart performance, user-friendliness, and intuitive control at its best.

Novelties in PicConnect

With PicConnect, Picanol is centralizing its digital tools and services in one new fully digital platform. At ITMA 2023, visitors will be able to discover all the benefits and latest features of PicConnect to leverage the full extent of the possibilities offered by its Picanol weaving machines. Among other things, the recently released features such as alerting, access control, the action center, and the export of monitoring data should catch the attention of many visitors.

Below is the detailed overview of the Picanol machines and highlighted features:

Ultimax-4-R-220 Denim

Warp: Co Nm 17/1, Density: 19 ends/cm, Drawing in width: 210 cm

Weft: PBT Nm 22/1, Density: 18.5 picks/cm

Highlighted features: Recycled yarn ready • EcoFill 4c • Electronic Right Gripper Opener (ERGO) • Gripper stroke measurement • Gripper tape monitoring • Guided Gripper GC • Quick Style Change (QSC)

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • On-loom Picascope

Ultimax-8-R-360 Voile

Warp: Pes 76f24/800 dtex, Density: 30 ends/cm, Drawing in width: 336 cm

Weft: Pes 76 dtex + Pes 22 dtex +Pes 167 dtex + Pes 330 dtex + fancy Nm 3

Density: 18- 28 picks/cm

Highlighted features: OptiForce take-up • QuickStep weft presenter • On-loom Picascope • Tension Display (TED) • Electronic Filling Tensioner (EFT) • SmartCut • e-Leno

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • On-loom Picascope

Ultimax Terry-8-J-260 Terry towel

Warp: Ground: Co Nm 40/2, Pile: Co Nm 40/2, Density: 11 ends/cm, Drawing in width: 253 cm

Weft: Co Nm 27/1 + Co Nm 40/2 + Cv 500 dtex + Chenille Nm 8.5

Density: 19- 120 picks/cm

Highlighted features: Pneumatic pile backrest • Pile monitoring • Pile formation system • BlueTouch display • Guided Gripper GCv • Needle roller • Needle roll control

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • On-loom Picascope

Ultimax-12-J-340 Flat carpet

Warp: Pes 500f144 dtex, Density: 32 ends/cm, Drawing in width: 340 cm

Weft: Chenille Nm 3.5 + Cv Nm 27/4 + BCF 1900f363 dtex

Density: 35 picks/cm

Highlighted features: OptiForce take-up • Free Flight with raceboard (VB) • Electronic Right Gripper Opener (ERGO) • BlueBox electronic platform • BlueTouch display • Smart signal lights • SUMO drive concept

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Gripper stroke measurement • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation • On-loom Picascope

OptiMax-i Connect-4-P-430 Anti hail

Warp: PE 722 dtex – ø 0.32 mono, Density: 2.9 ends/cm, Drawing in width: 410 cm

Weft: PE 722 dtex – ø 0.32 mono

Density: 2.9 picks/cm

Highlighted features: Guided Positive Grippers (GPG) • Waste ribbon winder • Waste ribbon detection • Direct Warp Control (DWC) with rolling tubes 4 • New filling cutter for coarse yarns

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation

OptiMax-i Connect-4-R-540 Coating

Warp: Pes 1.100f210 dtex – TO, Density: 7 ends/cm, Drawing in width: 530 cm

Weft: Pes 1.100f210 dtex – TO

Density: 7 picks/cm

Highlighted features: Free Flight with raceboard (VB) • Electronic Right Gripper Opener (ERGO) • Direct Warp Control (DWC) • BlueTouch display • Smart signal lights • Laserstop

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use • AutoSens • Gripper tape monitoring

Optimization package: Power monitoring • Harness frame stroke measurement & Shed simulation

TerryPlus-i Connect-6-D-260 Terry towel

Warp: Ground: Co Nm 40/2, Pile: Co Nm 34/2, Density: 23 ends/cm, Drawing in width: 248 cm

Weft: Co Nm 40/2 + Co Nm 24/1, Density: 19.5 – 144 picks/cm

Highlighted features: Pile formation system • Pile monitoring • Pneumatic pile backrest • SmartShed • AirMaster • Needle roll control • Pick Repair Automation (PRA II Plus)

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

OmniPlus-i Connect-4-D-340 Sheeting

Warp: Co Nm 102/1, Density: 72 ends/cm, Drawing in width: 301 cm

Weft: Co Nm 68/1, Density: 41 picks/cm (Double pick)

Highlighted features: Twinjet • Air Tucking-In (ATI) • Electronic Selvedge System (ELSY) • SUMO drive concept • Sensor dashboard • OptiStyle • PicConnect enabled

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

OmniPlus-i Connect-4-D-190 Car seat

Warp: Pes 167f48 * 2 dtex, Density: 27 ends/cm, Drawing in width: 180 cm

Weft: Pes 167f48 * 2 dtex, Density: 27 picks/cm

Highlighted features: SmartShed • Blue11 EasySet prewinders • Picanol Knot Extractor (Full PKE) • Adaptive Relay Valve Drive (ARVD II Plus) • CordLess • Quick Style Change (QSC) • Raw material use

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO)• AutoSpeed • Harness frame stroke measurement & Shed simulation

OmniPlus-i Connect-4-P-190 Bottom weight (100% recycled yarn)

Warp: Pes/Co recycled (67/33) Nm 17/1, Density: 23.7 ends/cm, Drawing in width: 167 cm

Weft: Pes/Co recycled (67/33) Nm 28/1, Density: 26 picks/cm

Highlighted features: o-Leno • Blue22 EasySet prewinders • Pick Repair Automation (PRA II Plus) • hybrid harness frames • Shed angle indicators • BlueTouch display • Access control

Standard: BlueBox electronic platform • BlueTouch display • SUMO drive concept • Climate monitoring • Shed calculation • PicConnect enabled

Monitor package: Access control • OptiStyle • Raw material use

Smart savings package: Power monitoring • AirMaster with integrated air consumption meter • Adaptive Relay Valve Drive (ARVD II Plus)

Automation package: Pick Repair Automation (PRA II Plus) • Prewinder Switch-Off (PSO) • AutoSpeed • Harness frame stroke measurement & Shed simulation

PicConnect corner

Visit the PicConnect corner of our booth to discover everything you need to know about this platform. All of the weaving machines at our booth will be connected to PicConnect.

OmniPlus-i Connect-4-J-220 African damask (Stäubli – Hall 6 – Booth A201b)OptiMax-i Connect-12-J-190 (Vandewiele/Bonas – Hall 10 – Booth B201c)