Sublimation digital printing, renowned for its high precision, efficiency, and environmentally friendly process, delivers a range of significant advantages. Textiles produced with this technology exhibit vibrant colors, intricate patterns, well-defined gradients, and a striking three-dimensional effect.

Simplified and cost-effective production

This process effectively streamlines the complex steps of traditional printing. First, sublimation ink is printed onto transfer paper.

Then, under specific temperatures, the ink is transferred to the substrate—typically polyester fabric. This method significantly improves production efficiency, reduces production cycles, and lowers costs, making it the dominant technique for polyester textile printing.

Market growth and dominance

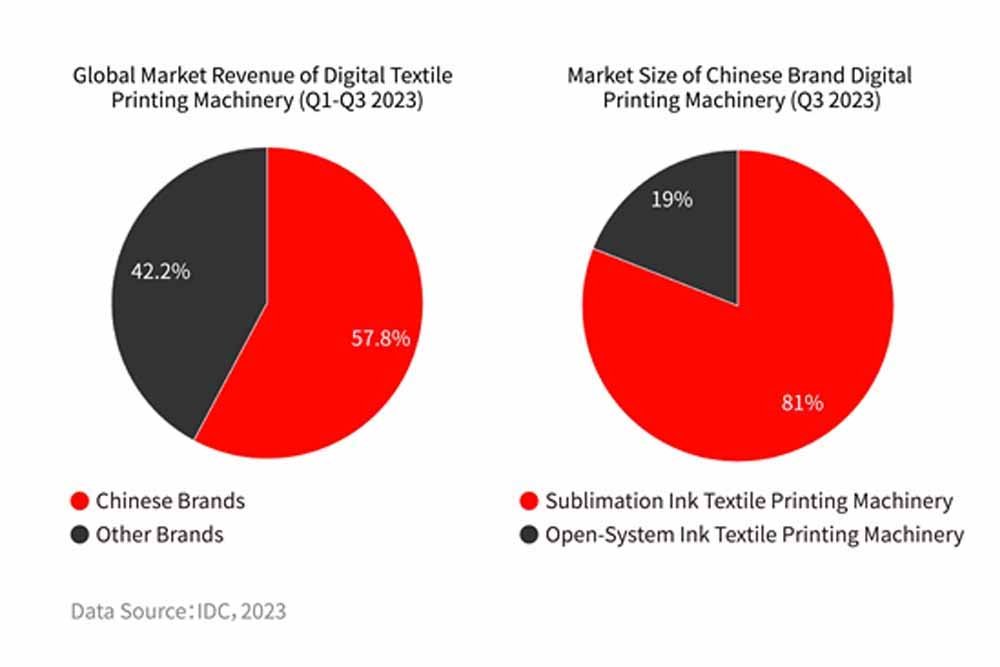

In recent years, Chinese digital textile printers have steadily expanded in overseas markets, maintaining consistent growth. IDC data shows that Chinese sublimation inkjet printing machinery has seen significant growth, with a market share reaching 81% by Q3 2023. Accordingly, due to its cost advantages and sustainability benefits, sublimation ink has demonstrated strong market adaptability and competitiveness in the markets of several countries, including India, Bangladesh, Indonesia, Italy, Switzerland, and Brazil.

Overall, sublimation inks continue to experience growing demand across a wide range of industries, including apparel, home decoration, home textiles etc.

Different application scenarios demand stricter ink performance standards

In the fashion industry, sublimation inks must deliver exceptional color reproduction. For outdoor sportswear, high UV resistance and wash fastness are critical. In-home decoration, textiles such as curtains require excellent dry and wet rub fastness, as well as lightfastness, to ensure long-lasting durability and visual appeal.

In response, INKBANK offers a range of effective ink solutions specifically designed for polyester textile digital printing applications:

INKBANK® Ultra-High Concentration Sublimation Ink achieves deep color intensity without increasing ink volume.

INKBANK® High-Penetration Sublimation Ink minimizes white spots caused by insufficient dye penetration.

INKBANK® High-Fastness Sublimation Ink maintains stable color clarity and fastness in prolonged high-temperature environments.

INKBANK® High-Brightness Sublimation Ink offers high color saturation and purity for striking visual effects on textiles.

INKBANK® Low-Gram/Coating-Free Paper Sublimation Ink reduces chemical usage and energy consumption, enabling higher profit margins.