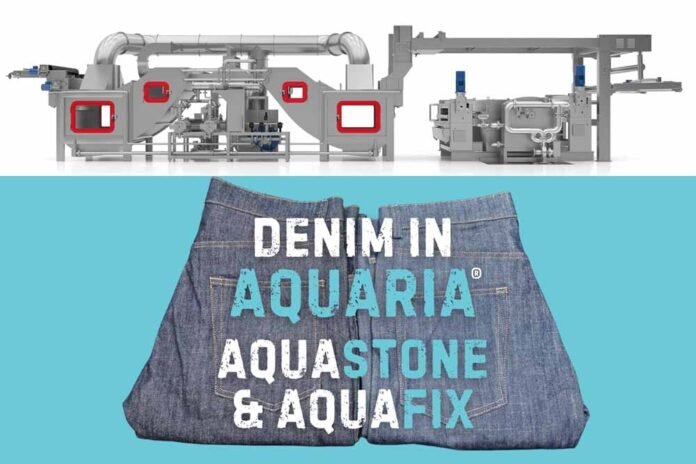

The textile industry is experiencing a revolution in the finishing treatments of Denim fabrics. Biancalani Textile Machinery introduces a set of processes by AQUARIA®, specifically thought for professionals in the industry.

Denim is one of the most versatile fabrics and demands ultra-modern treatments to gain a competitive position in the textile market.

The main challenge when it comes to Denim treatment has always been shrinkage, or better, pre-shrinkage.

So far, this process has been performed by stenters, machineries that perform fabric stabilization but don’t address the shrinking problem directly. AQUARIA® stands out in the textile market exactly because it performs an actual pre-shrinking process, thanks to the innovative processes AQUASTONE and AQUAFIX.

Only after these treatments can the stabilizing phase be successful. The result is simply remarkable: while usually an annoying dimensional instability somehow persists in stretch fabrics, bringing to a 15-20% shrinkage both in the warp and weft, with AQUAFIX in AQUARIA® can enhance fabric stability by lowering that percentage to a 3-4%.

With AQUARIA®, Denim washing processes are performed in continuous and open width, ensuring three key benefits: significant cost savings, environmental sustainability, and superior quality.

Sustainability and cost savings are AQUARIA®’s main features that can make the difference in Denim finishing, especially when it comes to large productions.

But the real step forward is treatment uniformity. The traditional laundry process shows a significant difficulty: every 250-500 garments, the machine has to be unloaded and reloaded, with the actual risk of getting non-uniform results between one and the other batch.

The unique AQUASTONE process by Biancalani solves the problem thanks to a pre-stonewashing phase in the fabric piece, ensuring a uniform effect, more resistance, and superior quality. This innovative approach prevents stress rips in the most critical garment parts.

An added benefit is the considerable savings as per laser and chemical products that are usually necessary during the in-garment laundry phase, because the fabric gets to the tailoring phase already pre-washed.

AQUASTONE by AQUARIA® stands as a real breakthrough in Denim finishing treatments and pre-washing. Not only does this process maximize the following product phases, but it also significantly reduces production times, energy consumption, and the use of chemical products. The final result is a superior-quality product obtained thanks to a continuous and repeatable process that is more sustainable and effective.

This technology is a real step forward in the Denim industry, as it combines industrial production needs with high-quality standards and an eye for environmental sustainability. Treating fabrics uniformly and continuously while reducing environmental impact and production costs makes AQUARIA® an advanced solution tailored to meet the evolving demands of the textile industry.