Denim remains a staple in textiles, valued for durability and versatility. However, achieving deep, vibrant colors with reactive dyeing has been a challenge, particularly in Pakistan.

Many factories have struggled to implement this method on rope and slasher dyeing machines—until DyStar’s breakthrough.

Perfecting Reactive Dyeing

DyStar, a global leader in dyeing solutions, tackled the challenges of reactive dyeing through rigorous trials. Led by Faisal Mumtaz and Mansoor Ghaffar, the local team refined processes to achieve exceptional results.

Overcoming Technical Challenges

Reactive dyeing often posed difficulties due to high-volume dye baths and rope-form materials. “Our machines were not originally designed for this,” said Mansoor Ghaffar.

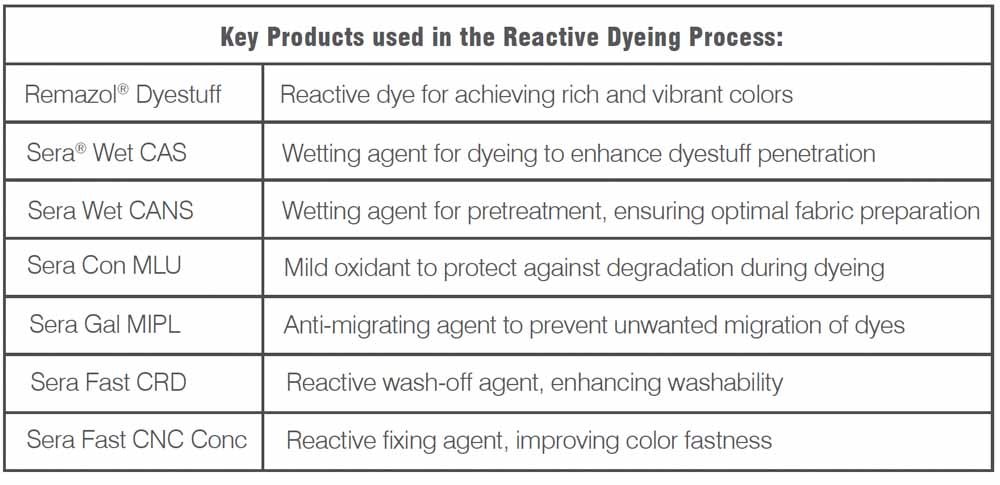

“We addressed this by implementing the Pad Dry Chemical Pad Steam (PDCPS) method at minimal levels, ensuring optimal feed ratio. Adjusting machine speed was crucial for handling rope-formed materials.” Through process optimization and DyStar’s advanced auxiliaries – Sera Wet CAS, denim manufacturers are now achieving superior dye penetration and fixation while maintaining durability standards.

Limitations with Reactive Dyeing on Denim

While reactive dyeing delivers vibrant colors, achieving solid shades without washing down remains a challenge. DyStar technical team came up with tailored solutions to mitigate this issue, ensuring deep, rich hues with enhanced fastness that meet stringent industry standards for durability and performance.

The Future of Denim with Reactive Dyeing

By using reactive dyeing, denim manufacturers can now produce fabrics that do not compromise color depth or fastness. The ability to achieve vibrant hues without sacrificing performance has opened a new world of possibilities for denim brands. As customer demand continues to evolve towards more dynamic and colorful offerings, DyStar’s successful implementation of reactive dyes allows factories in Pakistan to remain competitive and relevant in a saturated market.

Conclusion

DyStar’s successful trials with reactive dyeing for denim in Pakistan are more than just a technical achievement; they represent a significant step forward or the entire textile industry. With the backing of a dedicated team and a commitment to excellence, DyStar is leading the charge in providing sustainable, high-quality solutions to textile professionals around the globe, positioning denim manufacturers for success in an increasingly competitive market.

DyStar, Remazol, and Sera are registered trademarks of DyStar Colours Distribution GmbH, DE.