At the ITMA ASIA + CITME, KARL MAYER is presenting innovations in its core technology areas of warp knitting and warp preparation at its 360 m² stand A 301 in Hall 5 of the Singapore EXPO under the motto: WE WARP. WE KNIT. WE CARE.

Highlights include a textile showroom, two new warp knitting machines for the production of sought-after fashion items, solutions for warp preparation in weaving with a focus on an optimised price-performance ratio, and technical textiles that open doors to new business potential.

WE KNIT FASHION: textile show with real “wow” effects offering inspiration and more

Customers are champions in their fields of application and demonstrate passion and vision in driving textile ideas forward. KARL MAYER supports them in this quest – including with textile innovations that showcase the potential of its technology, open doors to new business areas and collaborations, and are designed to truly inspire.

An extensive textile showroom displays exclusive fashion items and textiles with a focus on comfort, durability & performance, style & trends, and fair prices.

Product and trend highlights in the Tricot Fashion segment include:

• Fancy seersucker wear & new seersucker items with a unique, striking texture

• Formal woven-like outfits

• Trendy sneakers

• Comfortable athleisure fashion, including terry cloth items

• Classic corduroy clothing & new corduroy variations, including original turtle velvet looks

• Beach and swimwear featuring sun protection. Items made from elastic fabrics produced on two-bar tricot machines are the top sellers of the summer season.

The Lace & Raschel Fashion division has two innovations in store in terms of design and pattern:

• A comfortable everyday all-rounder with a pyjama cut made from RASCHELTRONIC® fabric

• A new solution for the production of high-quality bi-elastic TEXTRONIC® lace items at costs that make high-end manufacturing lucrative.

Double Needle Bar Raschel Fashion showcases popular applications, including:

• Stylish casual shoes to match any athleisure outfit

• Cosy faux fur clothing – a must-have for the coming winter season!

Anyone wanting to drive innovation also has to work with the up-and-coming generation. In a special area of the Textile Showroom, experimental designer fashion items are presented, the result of collaboration with the Niederrhein University of Applied Sciences Textile Department.

New machinery: lower costs, higher productivity

Two new tricot machines demonstrate how trendy fashion items can be produced efficiently.

In the field of two-bar tricot machines for elastic fabrics, in which KARL MAYER is the undisputed market leader, the next generation of machinery is being launched. The new machine makes a significant contribution to improving margins for KARL MAYER’s customers.

In the four-bar knitting machine segment, an attractive solution for the fashion & apparel segment is presented, tailored to suit specific regions and textile trends.

Both machines demonstrate their capabilities in the production of trendy apparel items at the trade fair.

WE KNIT TECHNICAL TEXTILES: Solutions for more and new business

The products produced using KARL MAYER’s machines with weft insertion and composite machines are extremely versatile. The ways in which they can be used are equally diverse. At the trade fair, two areas of application with considerable future potential are in the spotlight: filtration and construction.

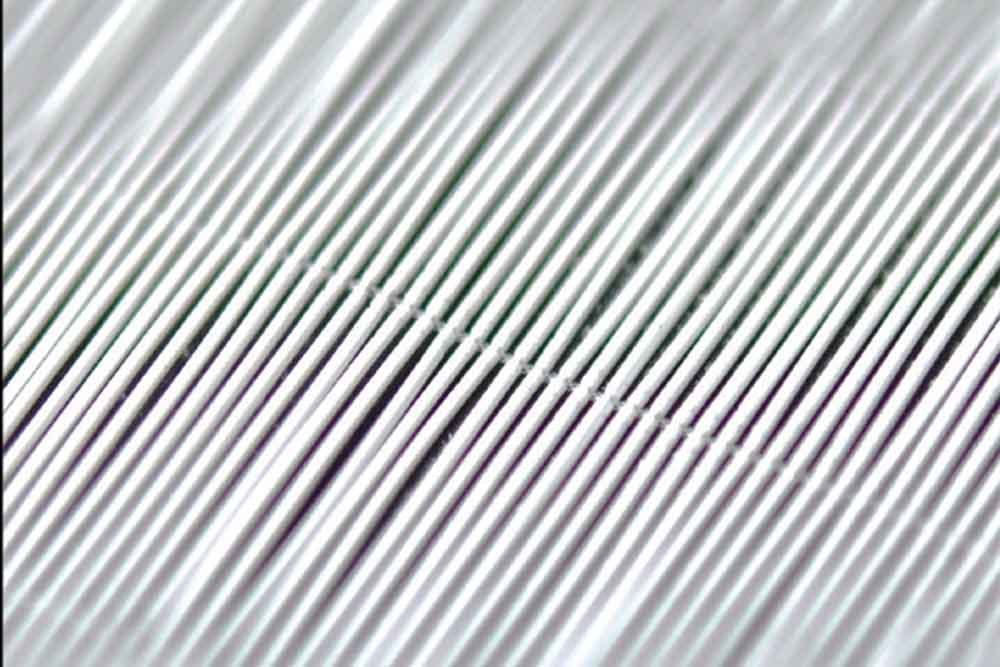

For filtration, the WEFTTRONIC II RSP weft insertion machine produces mats made of hollow fibres with porous surfaces using the principle of membrane filtration: gases and impurities are transported across the surface, while the feed medium flows through the fibre. This process is used, for example, for carbon dioxide injection in the beer brewing process, degassing of printer cartridge ink or oxygen enrichment of blood. During processing on the machine, the sensitive hollow fibres are treated with extreme care. Any changes in cross-section are avoided so as to ensure the highest filter quality and flow rates.

KARL MAYER machines produce high-performance textile solutions from technical fibres for the construction industry, helping to save costs and resources. Examples include:

• Reinforcement grids from the WEFTTRONIC II G, which protect road surfaces from cracking and rutting in road construction

• Concrete reinforcement instead of steel reinforcement, which reduces the CO2 footprint and costs

• Plaster grids, which prevent cracks from forming and spreading, and also ensure durable facade cladding. They can be produced much more efficiently on the WEFT GRID ECO than on weaving machines. Its output of plaster grids is up to 12 times higher than that of weaving machines for dense variants, and up to 17 times higher for open structures

• Coating carriers from WEFTTRONIC® II RS for cost-efficient and durable roofing solutions

WE WARP FOR YOUR SUCCESS

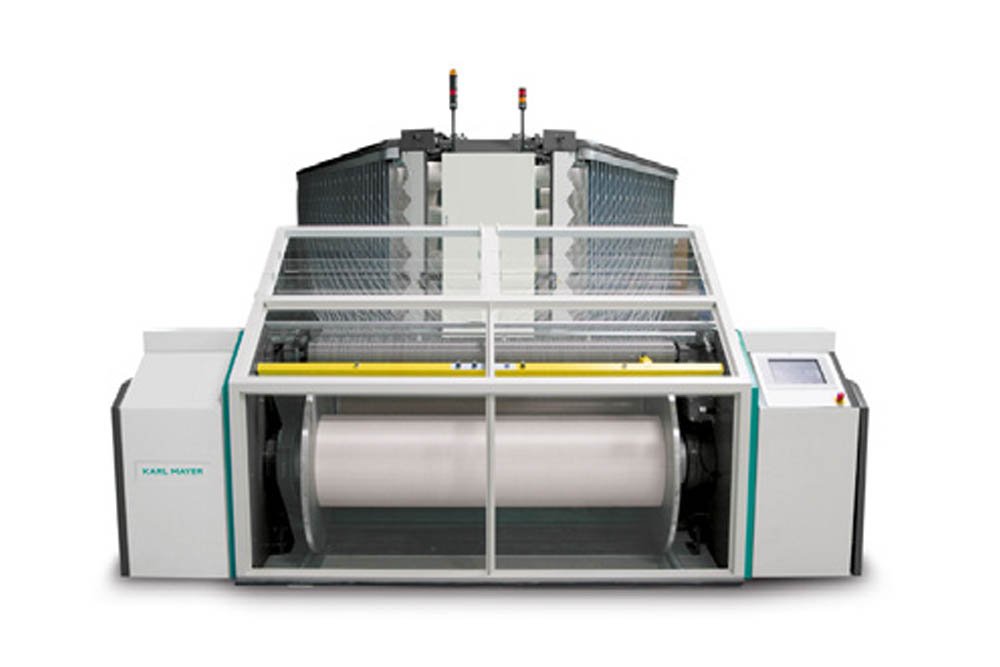

For warp preparation, KARL MAYER presents solutions from its broad product portfolio with a focus on lower production costs, greater availability and maximum reproducibility.

CASCADE is an innovative steam and condensation system that reduces the energy consumption of PROSIZE, lowering costs and reducing the environmental impact.

WARPDIRECT offers a convincing combination of unique output and high-quality beams, which enable less yarn waste and maximum efficiency in subsequent processes at a low cost.

Another focus is on digital solutions for predictive maintenance and condition monitoring, thereby increasing machine availability.