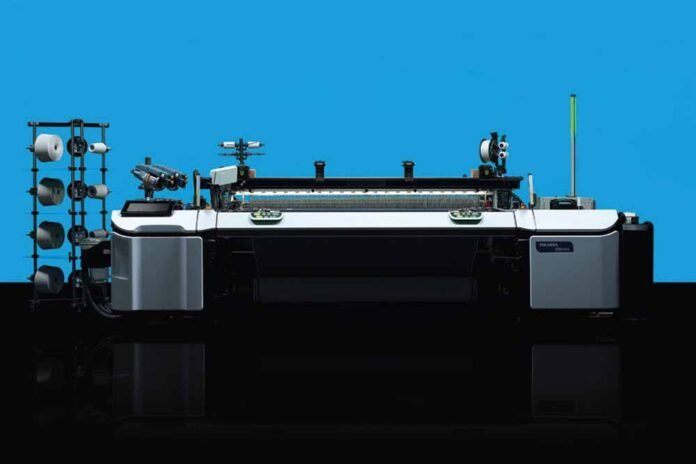

For more than eighty years, Picanol has played a pioneering role in the global textile industry and it is currently one of the world’s leading weaving machine manufacturers. Picanol develops, manufactures, and sells high-tech weaving machines based on air-jet and rapier technology. Picanol’s revolutionary rapier weaving machine, the Ultimax, focuses on three main benefits: ultimate performance and high-quality output, readiness for the sustainability requirements of tomorrow, and the greatest ease of use thanks to a maximum level of digitalization.

In addition, the classic Picanol exterior design of the machine has been radically disrupted to make it clear from the outside just how revolutionary the Ultimax is on the inside. The Ultimax excels in the fields of performance and quality, it has been designed with sustainability as the baseline, and the high degree of digitalization results in a previously unseen ease of use.

Ultimax-4-R-2020 Denim

Warp: Co Ne 10/1, Density: 19 ends/cmDrawing in width: 210 cmWeft: PBT Ne 13/1, Density: 18.5 picks/cm

Highlighted features: Recycled yarn ready, EcoFill 4c, Electronic Right Gripper Opener (ERGO), Gripper stroke measurement, Gripper tape monitoring, Guided Gripper GC, and Quick Style Change (QSC).

Standard: BlueBox electronic platform, BlueTouch display, SUMO drive concept, Gripper stroke Picanol Ultimax.Picanol Ultimax 4-R-220 Denim.

67 measurement, Climate monitoring, Shed calculation and PicConnect enabled.

Monitor package: Access control, OptiStyle, Raw material use, AutoSens filling detector and Gripper tape monitoring.

Optimization package: Power monitoring, Harness frame stroke measurement & Shed simulation, on-loom Picascope.

Ultimax-8-R-360 Fancy voile

Warp: Pes 68f24/800 den, Density: 30 ends/cm Drawing in width: 336 cm Weft: Pes 68 den + Pes 20 den + Pes 150 den + Pes 300 den + fancy Ne 1.8, Density: 18 – 28 picks/cm Highlighted features: OptiForce take-up, QuickStep weft presenter, on-loom Picascope, Tension Display (TED), Electronic Filling Tensioner (EFT), SmartCut and e-Leno.

Standard: BlueBox electronic platform, BlueTouch display, SUMO drive concept, Gripper stroke measurement, Climate monitoring, Shed calculation and PicConnect enabled. Monitor package: Access control, OptiStyle, Raw material use, AutoSens filling detector and Gripper tape monitoring.

Optimization package: Power monitoring, Harness frame stroke measurement & Shed simulation and on-loom Picascope

Ultimax Terry-8-R-260 Terry towel

Warp: Ground: Co Ne 20/2, Pile: Co Ne 24/2, Density: 23 ends/cm Drawing in width: 251 cm Weft: Co Ne 14/1 + Co Ne 24/2 + Chenille Ne 4, Density: 16 – 60 picks/cm Highlighted features: Pneumatic pile backrest, Pile monitoring, Pile formation system, BlueTouch display, Guided Gripper GCv, Needle roller and Needle roll control.

Standard: BlueBox electronic platform, BlueTouch display, SUMO drive concept, Gripper stroke measurement, Climate monitoring, Shed calculation and PicConnect enabled. Monitor package: Access control, OptiStyle, Raw material use, AutoSens filling detector and Gripper tape monitoring.

Optimization package: Power monitoring, Harness frame stroke measurement & Shed simulation and on-loom Picascope.