Since its establishment in 1955, Loepfe has been the pacesetter for innovation in yarn quality control. Loepfe researches, develops, and manufactures clever sensor systems in Switzerland to meet the needs of producers. They have excelled in sensor technologies for yarn and filament monitoring worldwide.

Loepfe has redefined the landscape in textile manufacturing through cutting-edge sensor technology. For decades, Loepfe has been at the forefront of revolutionizing the textile industry, elevating the standards of quality and precision.

Loepfe’s sensors are designed to deliver unparalleled accuracy in detecting even the slightest imperfections in yarns before they are processed into fabrics.

Clever Yarn Clearing

Clever yarn clearing for winding combines superior yarn clearing performance with great value. Loepfe’s PRISMA is the solution for spinning mills that need high-quality yarns at maximum machine efficiency.

As the only yarn clearer on the market featuring comprehensive four-sensor measurement methods, PRISMA stands out as the most advanced yarn monitoring system for basic, foreign matter, and polypropylene clearing. Reduce costs, enhance efficiency, and improve yarn quality with PRISMA, the clever choice for modern spinning mills.

The missing piece in compact yarn spinning

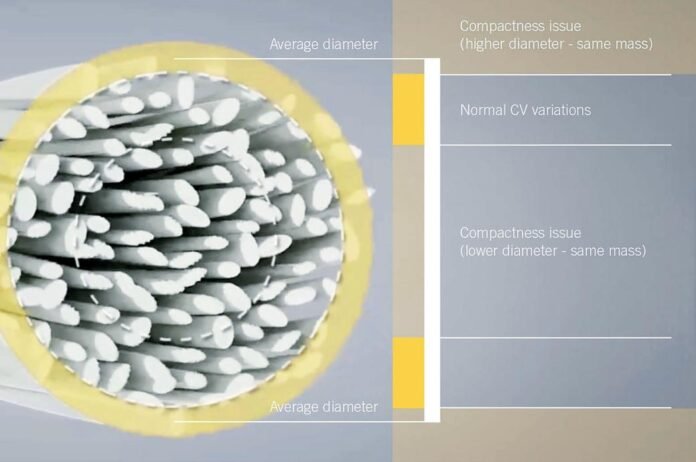

For a few months, the YarnMaster® PRISMA yarn clearer has served with its latest Compactness feature and empowers precision in yarn compactness monitoring. The Compactness feature is poised to become an essential tool in the world of compact yarn spinning. Designed with PRISMA’s signature cleverness, the Compactness feature brings unmatched precision in detecting longer faults, twist deviations, hairiness, and compactness differences. But that’s not all – PRISMA’s focus on minimizing waste and optimizing raw material utilization is at the forefront with the Compactness feature. By precisely eliminating detected twist errors throughout their length, unnecessary yarn waste is significantly reduced, leading to better efficiency and cost savings.

By integrating the Compactness feature, every spinner gains the remarkable capability to swiftly detect even the subtlest twist variations. This empowers them to maintain consistent yarn quality and avoid costly complaints due to yarn breaks, for example, during the weaving process, while also identifying and addressing the sources in previous process steps.

Compactness, in the context of yarn, refers to the tightness and uniformity of fibers within the yarn structure. PRISMA’s simultaneous dual measurement technique provides precise data on mass and diameter across every inch of the yarn, ensuring reliable results about any compactness issues and the successful production of various types of compact or conventional yarns.