Covestro succeeded in making elastic textile fibers containing CO2 and partly replacing

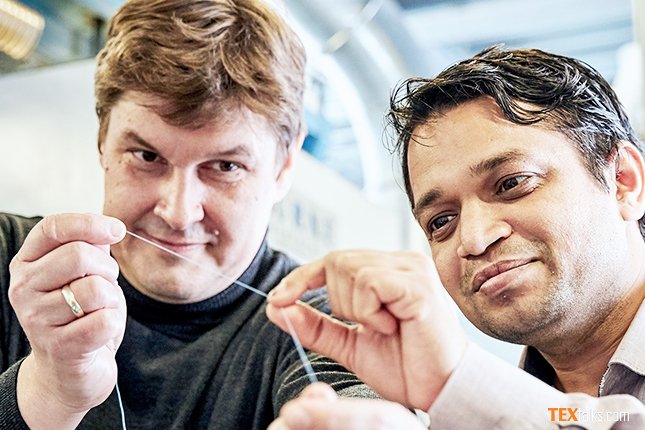

crude oil as a raw material. Covestro is working with university partners and various textile manufacturers to develop the production process on an industrial scale and make the innovative fibers ready for the market.

They can be used for socks and medical textiles, for example, and could replace conventional elastic fibers based on crude oil. The elastic fibers are made with cardyon®, a chemical component that consists of CO2 instead of oil.

Dr. Markus Steilemann, CEO of Covestro, said, “Our goal is to use CO₂ in more and more applications in a circular economy process and save crude oil.”

Dr. Markus Steilemann, CEO of Covestro, said, “Our goal is to use CO₂ in more and more applications in a circular economy process and save crude oil.”

Earlier, Covestro has already proven how carbon dioxide (CO₂) can be used to produce soft polyurethane foam for mattresses and upholstered furniture. TPU fibers containing CO2 can be used in textile fabrics. Initial companies from the textile and medical engineering sectors have already tested the fibers and processed them into yarns, socks, compression tubes, and tapes.

The aim of launching textiles that incorporate CO2 on the market is to promote a material cycle in the textile and clothing industry based on sustainable resources.

The fibers are made from cardyon®-based thermoplastic polyurethane (TPU) using a melt spinning technique. A new chemical method enables carbon dioxide to be incorporated into the base material of the fibers.

With CO2 as an alternative raw material, a solvent-free spinning process, and a presumably lower CO2 footprint, the material containing CO2 could become a sustainable alternative to conventional elastic fibers shortly.