The modern weaver faces many challenges: Digitalization is advancing deeper and deeper into the fabric of the production chain, sustainability requirements are growing more demanding, new employees and experienced technicians are thin on the ground. Flexibility in manufacturing is turning into an existential question. At the upcoming ITMA, DORNIER will present answers to these trends – in the form of the latest weaving machines and weaving solutions.

“We strive to design and manufacture our products so that they are as safe and environmentally compatible as possible.” This commitment was formulated by the company founder, Peter Dornier over three decades ago.

Our presence at the upcoming ITMA exhibition – the International Textile Machinery Exhibition – is further proof that sustainability is not just a passing fashion at DORNIER, but rather the foundation and result of a long-term corporate strategy. At this event, under the banner theme of “The Green Machine” we will present the latest machines and lines, “Made in Germany” for the sustainable, efficient manufacture of clothing, home textiles and technical fabrics and flexible, economical production of high-quality composite semi-finished materials.

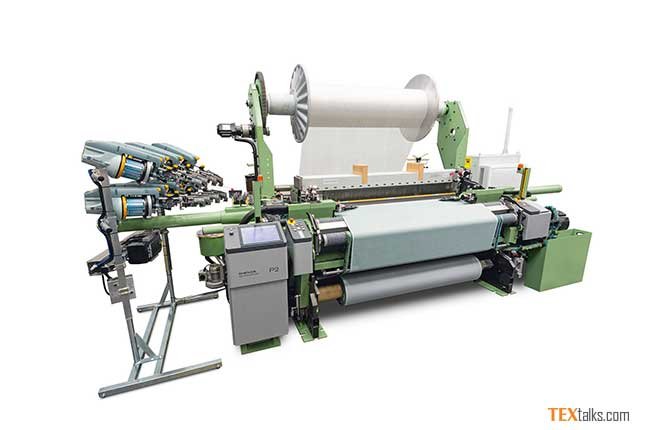

World premiere of the new rapier weaving machine P2

Highlights include the new rapier weaving machine P2, which will be presented in its standard configuration for the first time in Barcelona. It combines the strengths of the P1 All-rounder with many innovations to equip the weaver optimally for the future. “We didn’t reinvent rapier weaving, but we improved every major aspect of the process”, says Thomas Laukamp, DORNIER’s Head of Advanced Technology Development Weaving Machines. Accordingly, with improved shed geometry and a more rigid frame, greater productivity, maintenance-free operation and optimized positive center transfer movement, the P2 rapier weaving machine offers the highest flexibility and process reliability available on the world market.

Besides, the P2 was the perfect example of a technology approach conceived for total sustainability: Not only did the ultrafine precision fabrics it produced keep air and water clean or filter exhaust gases, the machine itself was designed for sustainability:“The resource-saving operating principle and long service life of the P2 make it a truly ‘Green Machine’”, says Head of Advanced Technology Development Laukamp.

Future-oriented: The encapsulated air-jet weaving machine

On the subject of air-jet weaving, DORNIER will exhibit an encapsulated air-jet weaving machine. This solution is designed to bring different, individually controllable climate zones into the production workshop for the first time: This means that each weaving machine can be run in its own climate, adjusted to create the ideal conditions for the respective manufacturing process, regardless of the heat and humidity in the rest of the production workshop.