The Alpha Series is designed to solve the current challenges of the industrial textile finishing sector: It features a sustainable and eco-friendly print technology and is designed for economic productivity and efficient processes, it minimizes warehousing by just-in-time production and produces top print quality with unlimited color and design complexity.

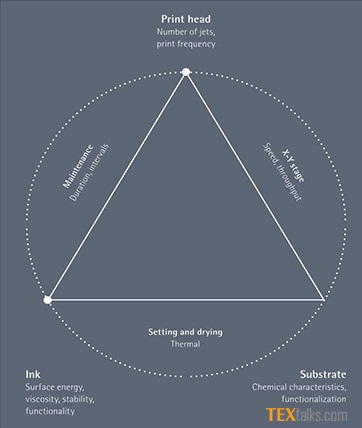

The Alpha Series combines new process technologies to control the interactions of print heads, ink system, textile material, fabric type, pre-treatment and finishing, thereby making them reproducible with the best performance.

Alpha 330-Multi Pass Textile

The new Alpha Series features different configurations and print widths for the digital printing of fashion garment and apparel, home textiles and upholstery.

The Alpha 330 is Durst ́s flagship for the industrial production of home textiles; with a maximum printing width of 330 cm, households and decor products such as duvets, linen, table cloths, curtains and drapes, as well as advertising materials such as flags and banners can be printed in their full width.

Depending on the number of print heads, the production output can vary: fully configured with 64 print heads the Alpha 330 produces up to 460 running meters per hour and the Alpha 190 up to 620 running meters per hour.

Magnetic Linear Actuator

The print carriage, engineered by Durst, is equipped with magnetic linear actuation to achieve the highest precision print results. The carriage and print bridge form the basis for this precise, flawless, sharp-edged output, with 2 micro-meter tolerances.Technical Specification for Alpha 330 are as follow;

Print speed:

1-Pass 300 x 600 dpi, 460 lm/h, 1.470 m2/h

2-Pass 300 x 600 dpi, 230 lm/h, 735 m2/h

Printing width and material thickness:

Max. printing width: 3,300 mm, max. material thickness: 8 mm

Integrated entry for fabric rolls diam. 500 mm max.

Axial unwinder for jumbo-rolls and material feed system for optimum advancement and tension monitoring

Feed unit for folded textiles

Printing blanket:

With permanent adhesive and integrated washing system

Heated pressing roller

Airblade for automatic belt drying

Dryer:

Horizontal dryer with 3 passes:

Thermal air dryer of up to 150 °C; with either gas or electricity

Material discharge options:

Uproller for roll diameters up to 500 mm

Discharge unit for folded textiles

Axial unwinder for big rolls up to 2000 mm

Print heads:

32/64 Durst Alpha Slots, 8 colors symmetrically arranged (mirrored) print heads featuring 40,960/81,920 nozzles

Printing mode:

Variable droplet sizes of 7/14/21 pictoliters

Resolution:

Standard 300 x 600 dpi and 500 x 600 dpi