Terry weaving is a widespread specialization among textile weaving mills in Pakistan. It is a very demanding application, whether medium- or high-density fabric is being produced. Terry bindings involve heavy forces that must be handled by the shed-formation components such as the cam motion, rotary dobby or Jacquard machine. Thus, the machinery must be robust, and the weaving process must be efficient in order for the mill to produce terry fabric profitably. Providing automation equipment for weaving preparation and a wide range of renowned shedding machinery, Stäubli equips forward-thinking weaving companies to excel in the worldwide terry market.

Pakistan’s terry weavers have been relying on Stäubli shedding solutions for many decades. In frame weaving applications, cam motions used to be the commonest solution for perfect shed formation.

But in the past 10 years, with increasing demands for design complexity, density and production speed, terry weaving companies have begun investing in rotary dobbies, particularly in the renowned Stäubli S3000/S3200 series.

Today, Stäubli is present in Pakistan terry weaving mills with around 1,000 frame-weaving solutions (cam motions and dobbies).

Solid harness motions for uniform shed formation

Weaving with heavy loads at high speeds – that’s a task in which Stäubli rotary dobbies in combination with Stäubli harness motions excel. Available for air-jet weaving machines in formats with up to 20 lifting units, the S3000/S3200 rotary dobbies offer high load capacity and easy adjustment of the shed opening. Operating 16 or 20 lifting units involves significant forces and results in a very large shed opening. Here the reinforced Stäubli e32/33 harness motions perform perfectly. Featuring robust construction, they absorb the dynamic forces caused by the high-speed movement and the large shed opening. The e32/33 harness motions transmit each and every shed movement to the frames with high precision. An additional benefit for the weaving mill is that these transmission elements are maintenance free.

The optimal Jacquard system – a combination of Stäubli harness components and machinery

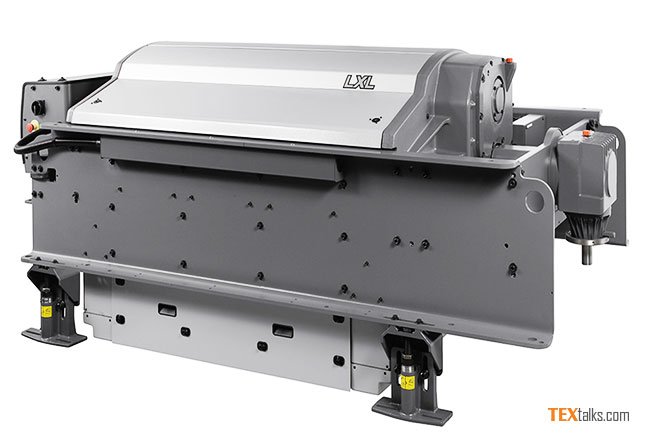

Jacquard terry weavers can count on LX/LXL/LXXL Jacquard machines to reliably handle heavy loads at the highest speeds. These machines are equipped with advanced NOEMI technology for hook selection. This technology consists of a redesigned electronic architecture and a reduced number of connectors, which assures extremely stable data transmission. Every Jacquard installation integrating the LX/LXL/LXXL machines is equipped with the JC7 controller, which can drive up to 100,000 hooks and allows for enhanced diagnostics. Using the pattern import functions this controller can transform a Stäubli dobby pattern into a Stäubli Jacquard pattern or adapt the pattern between two Jacquard machines with different number of module rows.

Jacquard terry weavers can count on LX/LXL/LXXL Jacquard machines to reliably handle heavy loads at the highest speeds. These machines are equipped with advanced NOEMI technology for hook selection. This technology consists of a redesigned electronic architecture and a reduced number of connectors, which assures extremely stable data transmission. Every Jacquard installation integrating the LX/LXL/LXXL machines is equipped with the JC7 controller, which can drive up to 100,000 hooks and allows for enhanced diagnostics. Using the pattern import functions this controller can transform a Stäubli dobby pattern into a Stäubli Jacquard pattern or adapt the pattern between two Jacquard machines with different number of module rows.

In order to realize the maximum benefits of a precisely matched Jacquard system, weavers can also invest in customized Stäubli Jacquard harnesses. These are made of high-quality harness cords and components such as QUICK LINKs that allow rapid harness installation and the new aluminum comber-board frame that improves heat dissipation. The harness springs with fastenings grouped in 2×8 for terry cloth are specially adapted with a vibration-reducing damping system. The sectional aluminum pulldown frame allows adjustment of the automatic BLOBAR blowing device to facilitate cleaning of the harness springs.

In order to realize the maximum benefits of a precisely matched Jacquard system, weavers can also invest in customized Stäubli Jacquard harnesses. These are made of high-quality harness cords and components such as QUICK LINKs that allow rapid harness installation and the new aluminum comber-board frame that improves heat dissipation. The harness springs with fastenings grouped in 2×8 for terry cloth are specially adapted with a vibration-reducing damping system. The sectional aluminum pulldown frame allows adjustment of the automatic BLOBAR blowing device to facilitate cleaning of the harness springs.

Terry weaving is a demanding task, but if the mill meets the key prerequisites, this application has its place even in difficult market times.

Any mills with know-how in terry weaving can benefit from Stäubli solutions and enhance their overall efficiency. Stäubli offers not only machinery, systems and components but also a global service network and spare parts availability even many years after the machine purchase.