The world-wide athletic apparel market grew significantly between 2009 and 2020. This market is further estimated to grow due to peoples growing awareness on sport and exercise in daily life, that will bring in US$ 207 billion in sales by 2025 (Source: https://www.statista.com). There are many new synthetic fabric manufactures set up and increased their production capacity in the last decade.

These growth statistics of athleisure products are encouraging knit processors to consider expansions and diversifications to meet the needs of this segment including new players from India and Bangladesh. Many investments are therefore being planned to tap the huge potential presented by this segment. Garment properties like protection, insulation, moisture permeability, stretch, shape retention, optimum heat and moisture regulation, rapid drying, dimensional stability even when wet, durable, easy care, light weight, soft touch, etc., are intrinsic to active wear garments. However, these properties are not readily achievable in 100% cotton, circular knitted fabrics. Hence the need for synthetic circular or warp knitted fabric production and processing becomes inevitable for addressing the opportunities in the active wear segment.

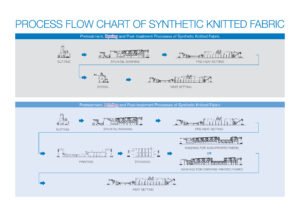

The very first step in synthetic active wear processing or spandex processing is spun oil washing (refer to diagram 1). Goller is a major international player in this segment and a major supplier in wet finishing lines for high end synthetic fabric manufacturers worldwide.

GOLLER – A brief introduction

GOLLER – A brief introduction

Goller was founded in Germany and produced first open width textile processing ranges in 1948. Goller became a member of the CHTC Fong’s Group in 2006. The integration of Goller into the CHTC Fong’s Group helped it to develop and spread at a tremendous rate with its highly engineered textile wet finishing ranges for the textile industry. Nowadays, Goller is one of global market leaders in the manufacturing of open width textile processing ranges and her wet processing ranges including those for spun oil washing are widely used to produce high quality woven and knitted fabric in world-wide textile dyeing factories.

Objectives of spun oil washing

Spun oil washing is a pre-treatment wet processing of synthetic woven or knitted (circular/warp knit) fabrics with appropriate de-oiling chemical agent to remove spun oils from yarn & fabric surface. These lubricants are applied in spinning process which remains on the fabric through the knitting process. The purpose of open width spun oil washing process is to make fabric pre-shrinkage, reduce and keep certain levelling of oil distribution on the fabric, and to thus ensure uniform dyeing and finishing results in subsequent finishing steps.

If a grey fabric with oils on it is heat set, there is an accumulation of these oils in the stenter. This creates chances of fire in the exhaust pipelines and in the heat exchangers. Oil dripping further creates quality problems in subsequent processing. But after spun oil washing, if the washed fabric is pre-heated and set, the stenter will remain oil-free and safe, eliminating risks of fire and improving fabric quality.

If a grey fabric with oils on it is heat set, there is an accumulation of these oils in the stenter. This creates chances of fire in the exhaust pipelines and in the heat exchangers. Oil dripping further creates quality problems in subsequent processing. But after spun oil washing, if the washed fabric is pre-heated and set, the stenter will remain oil-free and safe, eliminating risks of fire and improving fabric quality.

The benefits of Goller spun oil washing ranges:

• Avoids fire hazard in stenter while pre-setting

• Even dyeing results

• Pre shrinkage of fabric

• Suitable for wide range of fabrics from light to heavy gsm

• Environment-friendly process