![]() Baldwin Technology has been a pioneer of industrial automation for 100 years. Baldwin has developed a revolutionary technology for the textile finishing industry that eliminates chemical waste, reduces energy consumption in drying, and increases the capacity of the facility. So revolutionary, it has been installed in the North Carolina State University’s textile finishing and dying lab.

Baldwin Technology has been a pioneer of industrial automation for 100 years. Baldwin has developed a revolutionary technology for the textile finishing industry that eliminates chemical waste, reduces energy consumption in drying, and increases the capacity of the facility. So revolutionary, it has been installed in the North Carolina State University’s textile finishing and dying lab.

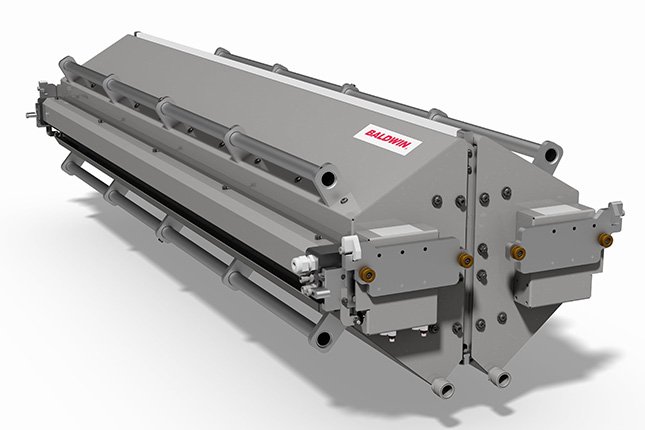

The product is called TexCoat™ G4 and is designed to enable the most eco-friendly and efficient application of water and chemicals such as finishing chemistries to fabrics and other surfaces as part of textile production processes. TexCoat™ G4 is a non-contact spray technology for textile finishing and remoistening, designed to allow a controlled and optimal coverage of the exact amount of finish chemistry for reaching specific characteristics of the fabric. The system can be used to reduce water consumption by as much as 50% compared to traditional padding application processes.

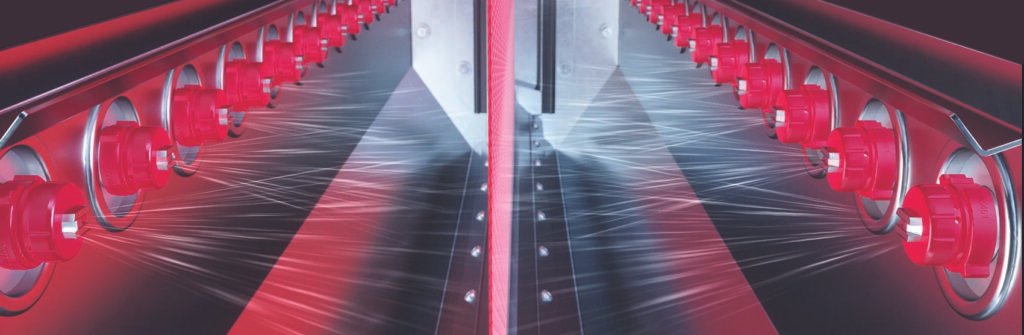

In operation, the TexCoat™ uses a precision spray application system to evenly apply water or chemistries to one or both sides of a moving web roll of fabric or other material, using an application system that spans the width of the web with evenly spaced spray nozzles. This “non-contact” method of applying liquids to surfaces is highly efficient and eco-friendly because the minimum required amount of water or chemistries can be used.

Mist contaminant covers prevent aerosols from escaping while chemistries are being applied, and exchangeable cassette valve rails enable the service of spray valves both offline and during operation, to minimize downtime. Systems can be used for wet-on-wet or wet-on-dry application; individual nozzle control allows for an added level of control over the chemistry or water application process.

A digital touchscreen control panel makes for easy operation of the system, and automatic valve failure detection adds the extra assurance that saves time.

TexCoat™ G4 enables a continuously high-quality finishing process with zero chemistry waste and minimizing water and energy consumption. It utilizes Precision Application Technology (PAT), a noncontact textile finishing system enabling a high spray intensity and deep impregnation, even on thick fabrics. In fabric or chemistry changeovers, 100% of the chemistry is recycled with zero waste. In combination with reduced energy, water, and chemical consumption, TexCoat™ G4 ensures a sustainable and financially beneficial textile finishing process.