Baldwin Technology Company Inc., has officially started its operations with its new partner Al-Ameen Trading Corporation at IGATEX 2022, Lahore, Pakistan. Initially, the company is focusing on introducing TexCoat G4 non-contact precision-spray technology that helps textile finishers up their game by enabling consistent, high-quality finishing with zero chemistry waste and drastically minimized water and energy consumption. Baldwin manufactures precision spray technology to apply softeners, antimicrobials, water-repellent chemicals, and water to fabric, film, paper, and other substrates. We also provide spray powder application systems.

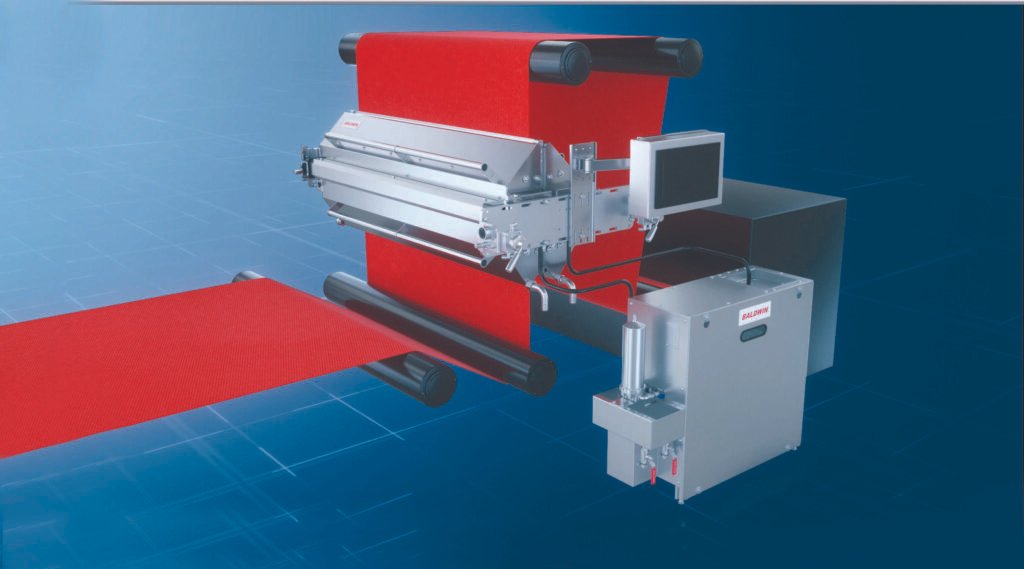

In operation, the TexCoat™ uses a precision spray application system to evenly apply water or chemistries to one or both sides of a moving web roll of fabric or other material, using an application system that spans the width of the web with evenly spaced spray nozzles. This “non-contact” method of applying liquids to surfaces is highly efficient and eco-friendly because the minimum required amount of water or chemistries can be used.

Rick Stanford, VP of Global Business Development, Textile at Baldwin, said, “We are very excited to kick-off in Pakistan through the platform of Al-Ameen Trading Corporation. Pakistan is a big textile market, and we have seen that customers are looking for sustainable textile technologies due to cost-saving and increasing energy prices. TexCoat G4 is the best choice for Pakistan’s finishing sector looking to reduce carbon and water footprints. Al-Ameen’s booth was very busy today, and we interacted with many potential customers. I believe that Pakistani textile business people are very focused on investing in new cutting-edge technologies. Thus, we are hopeful for a great impact and good penetration in the market.”

Noteworthy Benefits

- The system uses precision spray technology instead of padding or soaking/bath methods to saturate fabrics so that textile producers can see up to a 50% reduction in the amount of water or chemistries used in production.

- Producers can see a 50% reduction in their energy consumption, thanks to the ability to eliminate dryers – fabric is never over-saturated enough to need drying

- TexCoat™ enables huge time savings – drying time is eliminated, production times are sped up, and the system is quick and easy to service and maintain, thanks to features like tool-free exchange of the spray nozzles and exchangeable valve cassette rails