Modern textile machines are equipped with control systems that substantially reduce the energy, water, and chemicals consumption besides eliminating the waste of expensive raw materials. The advanced machines ensure massive reduction in environmental footprint.

All these innovative equipment and innovative technologies would be on display at the International Textile Machinery Association (ITMA) exhibition that which will be held in Milan, Italy, from June 8-14, 2023. It is the show that textile machinery manufacturers wait for the whole. But the technological innovations and disruptions have forced most of the new innovators to remain on their toes and pounce upon the opportunities they see outside the show. The world’s largest textile and garment technology showcase, ITMA will continue to present and share innovative manufacturing technology and materials with the industry at its 19th edition in Milan.

Nonetheless they cannot afford the ITMA show that brings together not only the best machine making companies but also the most important machine buyers of textile equipment from around the world. They would be showcasing their new innovative technologies that enhance process and product sustainability and promote digitization processes. There would be new machines at the show. Europe might have lost apparel production to emerging economies but the continent is still in lead as far as production of textile machinery is concerned. Italy, Switzerland and Germany are leaders in manufacturing quality textile equipment for the entire textile value chain.

All the innovative products are the result of collaboration between textile companies and their textile technology providers. New products and new applications of textiles arise from the creativity of both sectors and their synergy. Therefore, Italian textile machinery manufacturers are ready for the challenges that lie ahead thanks to their ability to collaborate daily with their customers and offer them technological solutions capable of creating increasingly innovative products. The prospective buyers will have the opportunity to choose various machines brands producing sustainable equipment that consume less water and less energy in the process.

Italian manufacturers’ would proudly come with ACIMIT project named “Sustainable Technologies”. The project was conceived in an effort to develop and promote key sustainability issues for the textile industry. The machines at display would carry Green Label certification in controlled and certified by a certification body, RINA, an expert on environmental performance of each machine. ACIMIT products would also come up with Digital Ready certification. This certification is accompanied with simple production process with standard language that could communicate with different machines in a process of a production system

Machine manufacturers realize that future growth would be in innovative textiles, encompassing sectors like automotive, construction, and medical ones. Recycling would gain momentum as time passes by because of environmental concerns. Prospects for growth of the nonwoven sector are also bright particularly in personal hygiene and in the medical sector.

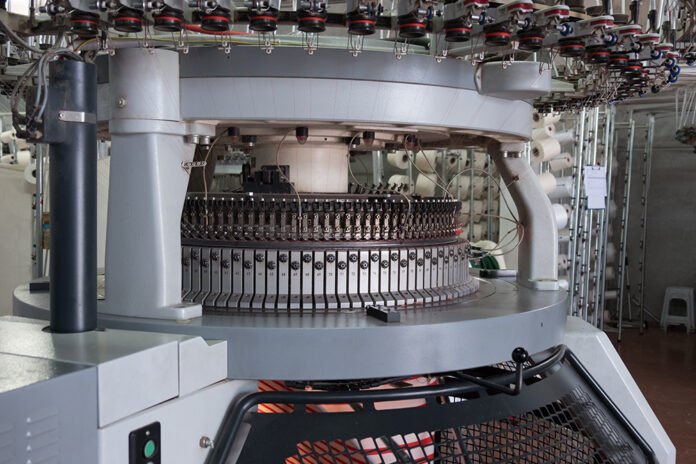

The Swiss carry a heritage of more than 4,000 years of expertise in textile machinery, components and services. They are well equipped and experienced to face new global innovative challenges. The Swiss firms offer solutions covering the entire textile value chain, from spinning and winding to weaving, knitting, finishing, nonwovens, embroidery, and quality control. Data offers various possibilities, in product or process optimisation and in the development of completely new business models. Swiss textile machinery companies use these possibilities to generate maximum customer benefit and help their partners in the transition to intelligent manufacturing. Swiss textile machinery today has a leading position in the high-quality segment of special machines and top-quality materials.

In Germany and other countries, an increasing amount of power we consume is produced by modern wind generators. The rotor blades of these generators are made of composites. German textile machines such as warp knitting machines, braiding machines etc are used to process fibre-reinforced composites. So, innovations in the textile machinery industry are the launch pad for intelligent applications and products. German textile machines such as warp knitting machines, braiding machines etc are used to process fibre-reinforced composites. So, innovations in the textile machinery industry are the launch pad for intelligent applications and products.

Life cycle costs and life cycle sustainability are optimised by developments in machine technology. Smart fabrics, 3D printed clothing, increased demand from the hygiene industry, and green textiles are changing the entire textile landscape and the industry is no longer the same as anyone knew it until a few years back. Given this scenario, prominent textile machinery associations from Europe share their view on how the industry is coping with the changes, the latest innovations and developments in the sector, and the future of the industry.