Dynamica Rope dyeing machine is a Green Label ACIMIT-certified product

MCS SpA is one of the leading name in the world’s textile machinery manufacturing industry founded by Mr. Chiappini, Mr. Cagnazzo and Mr. Sopegno in 1963. One year later MCS began its activity with the production of accessories for dyeing machines. The first low temperature rope dyeing machine was manufactured in 1967 followed by start of EUROPIZZI (dyeing-printing-producer of auxiliary products) within MCS Group. In 1971 at ITMA in Paris, MCS exhibited first low temperature jet model and the journey begins. TERMOELETTRONICA (a part of MCS Group) was acquired in the year 2000.

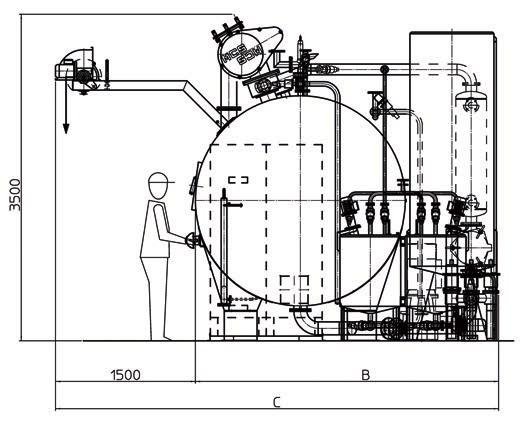

DYNAMICA allows to dye at low liquor ratio, down to 1:3,5. Furthermore, a multi-suction, vertical, centrifugal pump guarantees machine performances by reducing loads. The processes are faster and safer due to a new concept for product inlet (MCS patent) controller by industrial touch-screen PC (PCx-TEx by Termoelettronica).

WSS Water Saving System is the natural development of the concept that already resulted in VDA (View Dyeing Analyzer) in 2005. It is being applied in smaller size to all production machines. Using a colorimetric cell, all of the washing stages can be controlled and optimized to avoid all unnecessary consumption of water and products.

WSS Water Saving System is the natural development of the concept that already resulted in VDA (View Dyeing Analyzer) in 2005. It is being applied in smaller size to all production machines. Using a colorimetric cell, all of the washing stages can be controlled and optimized to avoid all unnecessary consumption of water and products.

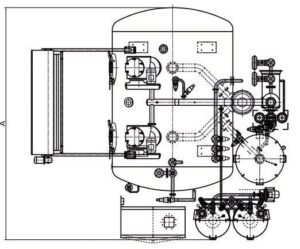

TSS Twin Saving System is the new connection system among machines of different capacities. In technical words, the solution is made viable by the development of the new MCS dosing system, which provide the conveyance of only a part of the flow of the dyeing liquor. The unbalance of the liquor is monitored by programmers which via analogue level reading, work out the corrections by opening or closing of the related valves.

Taking advantage of the pressure generated by the circulation pump and of the liquor inside the machine, by every liquor drain, the SSCF Self-Cleaning-Filter (patent pending) is being washed-off. This fact remarkably reduces the cleaning operations of filters and improves the performance of the circulation pump itself.

Taking advantage of the pressure generated by the circulation pump and of the liquor inside the machine, by every liquor drain, the SSCF Self-Cleaning-Filter (patent pending) is being washed-off. This fact remarkably reduces the cleaning operations of filters and improves the performance of the circulation pump itself.

Two side tanks for products, each one complete with its own mizer, pneumatic probe, heating coil, liquor recycling to make product dissolving and mixing much easier. Due to these equipment down times and waiting times are much reduced also in case of automatic dispensing systems.

MST (Machine Side Tank) is for liquor preparation; liquor is controlled and managed by a pneumatic probe in order to reduce down times by liqor fillings. MQD (Machine Quick Drain) by main circulation pump and HYDROVARIO is an adjustable section nozzle, electronically controlled which ensures maximum versatility in usage.