“We are happy to be able to return to participating in exhibitions after more than a year of lockdown. Starting again with ITMA, the most important exhibition in Asia, was a fitting occasion to compare with industry professionals and a precious opportunity to showcase the high value of Marzoli solutions for spinning. Our commitment to constant improvement represents added value for customers, who aspire to meet challenging new goals and grow in their target markets.” Lodovico Camozzi. President and Chief Executive Officer. The Camozzi Group

“We are happy to be able to return to participating in exhibitions after more than a year of lockdown. Starting again with ITMA, the most important exhibition in Asia, was a fitting occasion to compare with industry professionals and a precious opportunity to showcase the high value of Marzoli solutions for spinning. Our commitment to constant improvement represents added value for customers, who aspire to meet challenging new goals and grow in their target markets.” Lodovico Camozzi. President and Chief Executive Officer. The Camozzi Group

The phrase “Textile Engineering” – incorporated in the company’s logo – perfectly expresses Marzoli’s ability to innovate and work in close contact with customers, supporting them throughout all phases of the process. Services start with feasibility and preliminary studies and continue through plant construction, line start-up, optimization, management, and subsequent commissioning. Marzoli offers its services to all sizes of projects from a single machine to a complete spinning mill.

At ITMA Asia, Marzoli displayed its Draw Frame DFR1, which leads the field in terms of production capacity and yarn quality, thanks to 1000 m/min production and low CV%. Easy to operate, outstanding reliability, high flexibility, and low operational costs are key features of this world-class draw frame.

Digital Solutions

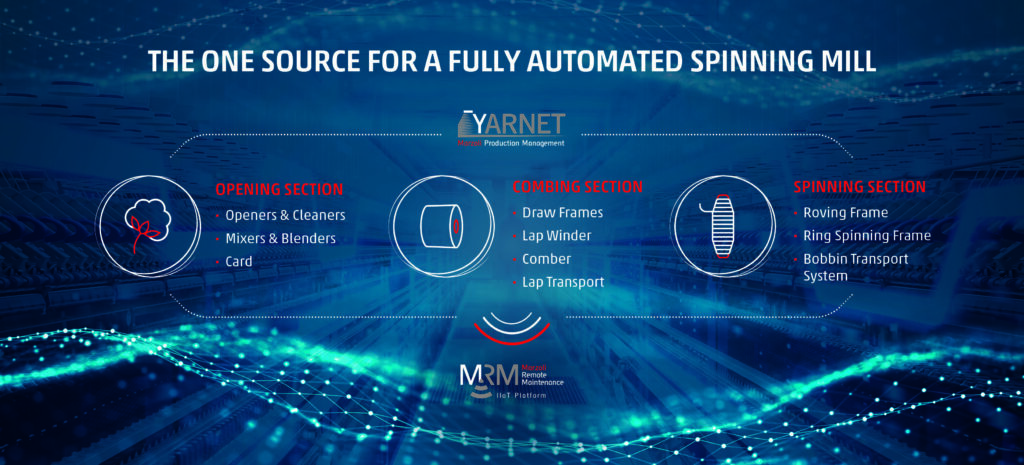

Another company strength is Marzoli’s expertise in developing the most advanced digital technologies which together create smart solutions for predictive maintenance, remote control, and plant management.

Marzoli has developed MRM (Marzoli Remote Maintenance): the world’s first patented software platform able to analyze Big Data generated by machinery processes and also to continuously monitor mission-critical operations. This ensures a reduction of machine downtime, longer useful life of parts, and more timely and effective maintenance.

Alongside this, integrated management can be enabled by YarNet, highly innovative software, through which users can easily manage the entire Marzoli spinning process directly from their PC. With it, every machine in a plant can be monitored with ease – a real value-added technology for customers aiming to maximize productivity and profitability.

Artificial Intelligence in Spinning Mills

Brain Box is a patented Marzoli software with an integrated APP, developed entirely in-house, which significantly improves plant performance. Tests confirm that Brain Box can generate a 5.5% increase in productivity, an 8% increase in efficiency, and 1.5% in energy savings. Installation is a fast and simple four-step process: mount sensors to each machine, connect the sensors to Brain Box, download the APP, and activate the monitoring function for the detection of any issues.

TAOMAPP is a new and innovative approach to cotton analysis in which the trash level inside the cotton is accurately determined through photographs taken by a smartphone. It is based on ultra-high resolution image recognition techniques and quantifies the results on the Marzoli Trash Index. You just need to download the app and start the analysis.

Trash Analyzer is an effective tool that, together with Marzoli software platforms, analyses cotton’s trash content to optimize machinery set up. It can be applied wherever there is a flow of material in a pipeline.