Silicone Softener made of Recycled and Renewable raw materials

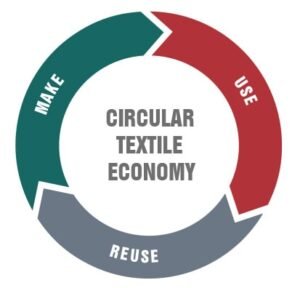

CHT Germany GmbH underline their commitment to sustainability by launching the first softener based on the concept of circular economy. With the traditional “take-make-use-waste” model every year the industry produces millions of tons of (textile) waste. For this reason a transition from this linear model to a circular economy with “take-makeuse-reuse” is necessary.

According to the concept of circular economy products are traded in “cycles”. Circular economy aims at optimally using resources, minimizing waste and ensuring less pollution. Waste presents problems all along the fashion supply chain: Every year, the present throw-away society and the corresponding linear “make-use-waste” model produces millions of tons of (textile) waste. This linear thinking strongly contributes to environmental pollution, climate change and depletion of finite resources. Ensuring long term sustainable prosperity which is in alignment with the United Nation’s (UN) Sustainable Development Goals – we believe that circular economy is the future and the right way to go.

For CHT, sustainability is not only a trend. It is one of the most important core values and correlates with the innovative strength of CHT. It defines daily work as well as our strategic focus. The CHT Group has great experience and a deep knowledge of all processes along the complete textile chain.

According to Robert Zyschka, Head of Application Field Finishing, CHT Group, “We started giving up traditional models and thinking more freely. To us the idea to create something new out of alleged waste was really fascinating and inspiring.”

As an innovative partner of the textile industry, CHT Group is working continuously on the ideas and solutions of tomorrow. Circular economy is a major topic, also for the CHT. The transition from a linear to a circular concept requires a joint effort and rethinking. Therefore, R&D, technical application experts and product safety are working closely with customers and brands to reach the common goals and accelarate innovation. CHT is pushing boundaries by transforming post-consumed products into new value streams.

CHT Reuse

CHT Reuse

CHT’s Circular System

Silicone is a versatile material that finds use in a wide range of different applications, and as such its commercial importance is significant. Silicones are an integral part of textile finishing as softeners, waterproofing agents, defoaming agents or lubricants. However, the production of silicones is extremely energy intensive. In order to fully exploit the value of this resource, end-of-life silicone products are recycled. As a result, today’s silicone waste can be used to produce an important alternative raw material for tomorrow.

Four stage Circular System

ReTake: Post-consumed products are taken and prepared for the next step.

ReGenerate: Through a radical regeneration and purification process, the post-consumed products are recycled back to their purity. The innovated reaction at CHT and the addition of renewable emulsifiers led to the ground-breaking TUBINGAL RISE.

ReMake: TUBINGAL RISE is processed into e.g. knitted or woven fabrics.

ReUse: New textiles are created with TUBINGAL RISE.

For a fully integrated end product of circularity, this softener can be applied on recycled fibres like rPES or rCO. These textiles have the potential to be used and subsequently recycled again.

New way of thinking – new way of creating

Post-consumed products normally become waste. CHT uses this post-consumed materials as new raw material. TUBINGAL RISE can be applied on new textiles. These textiles can be used and subsequently recycled back again. This represents a circular economy.