At SITEX 2026, the Swiss machinery group is selling Indian mills a productivity bundle—faster shedding, fewer style-change hours, and electronics tuned for energy savings.

Surat’s weaving economy runs on throughput. But power costs and downtime turn “more speed” into an expensive promise. At SITEX 2026 (Feb 21–23, Surat) Stäubli is presenting a portfolio framed around performance, reliability and power efficiency—the trio that actually determines loom profitability.

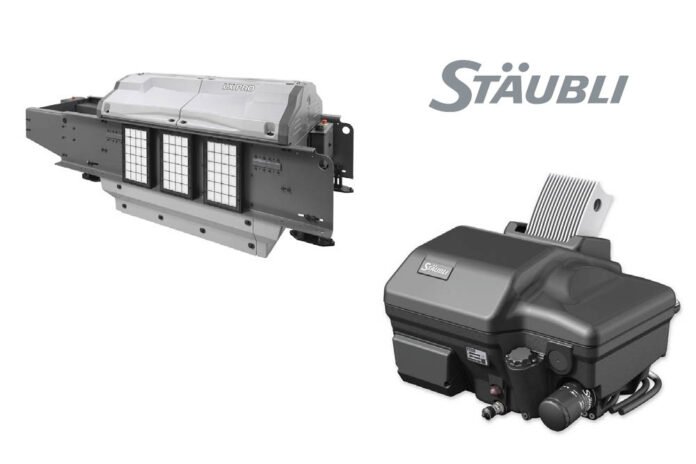

At Booth 242, Stäubli is spotlighting three choke points in weaving economics: shedding, Jacquard control, and warp preparation automation.

- S3018 rotary dobby (for water-jet weaving): positioned for high reactivity and stable high-speed lifting—useful for mills pushing versatility without sacrificing running stability.

- LX PRO Jacquard (shown for saree applications): equipped with TC8 controllers and NOEMI electronics, marketed for precision plus energy savings—attributes that matter in high-hook, high-speed patterning where errors are costly.

- SAFIR S32, TOPMATIC and TIEPRO: automation for drawing-in and warp tying, aimed at cutting downtime and accelerating style changes—often the hidden tax in high-mix weaving.

This is an “India-first” interpretation of global tech: not the newest feature, but the best payback—energy, stability, and faster changeovers. In Surat, where product cycles are short and competition is intense, reducing changeover friction can matter as much as raising peak rpm.

Mills will judge these systems on measurable outcomes: kWh per metre, fewer stops, cleaner sheds, and faster order switching. Stäubli’s real competitive claim is that robust mechanics plus smart electronics can turn those metrics into repeatable advantage—without demanding a full plant redesign.