“Weavers opting for Stäubli solutions are looking for machinery that is adapted to their needs to stay at the forefront of their market. Because we provide quality high-speed machinery made of first-class materials combined with ingenious R&D as a result of our long-lasting experience and partnering with our customers.”

High-speed weaving challenges the technical capabilities of weaving mills, but it is a necessary prerequisite for mills that want to remain successful in today’s textile markets. High-speed weaving increases productivity but calls for reliable machinery. At the same time, high quality standards must be upheld in order to produce a maximum volume of first-choice fabrics. Stäubli offers a wide range of leading-edge solutions – including unique and custom solutions for successful high-performance weaving in mills that are determined to remain one step ahead.

Achieving very high weaving speeds, whether on rapier, water, or air-jet machines, is the credo of weavers worldwide. The demands placed on frame or Jacquard weaving are constantly increasing, and the same applies to shed formation solutions.

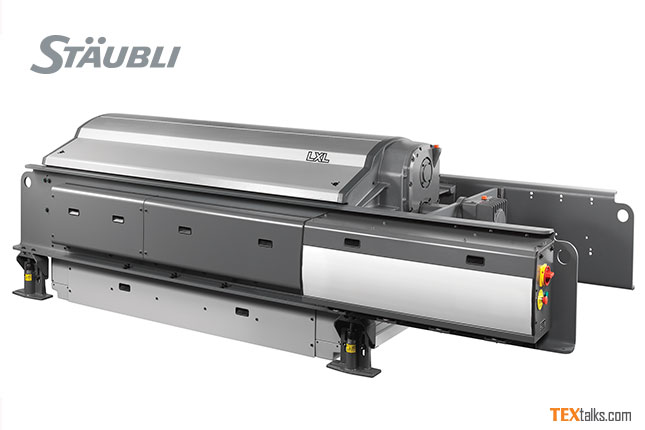

In Jacquard weaving, Stäubli provides the LX/LXL/LXXL high-speed Jacquard machines designed for heavy payloads at highest speeds. Very large formats of up to 51’200 hooks can run securely at optimal speeds. The reliable operation during these high speeds is supported by robust housing, perfectly balanced kinematics, an optimized airflow and the advanced technology for hook selection, namely the NOEMI electronics architecture. NOEMI shows off with a reduced quantity of connectors while ensuring extremely stable data transmission. With this electronics re-design the accessibility inside the machine has been substantially improved, making maintenance even easier. Each module is physically signaled by a LED, whilst the Jacquard controller rpeors detailed information. The overall concept is made for reliable high speed weaving for large formats and heavy payloads.

When it comes to frame weaving, Stäubli offers the lately launched S1792 cam motion for air-jet weaving, available in formats with up to 10 levers, and offering many concrete benefits to the weaver. Made of sturdy parts in high quality component the machine is made for enduring the usage. It features a fully integrated cooling system supporting optimized and regulated heat. Its shed levelling device is fully integrated into the machine and levels automatically (mechanically) the frames when the loom stops. Furthermore the lubrication is targeted for longer service lives and less maintenance. In addition the profits from innovative fine filtration with pre-filtration. And to ensure the perfect transmission, it comes along with the reinforced e32/33 harness motions. Integrating such an optimized combination into the weaving machine is a key to precise shed formation when the highest operating speeds are required.

High speed operating goes in equal with rapid warp yarn consumption and recurrent warp beam replacement. Downtimes are inevitable in this process, but for an efficient overall process, weavers should reduce these downtimes to a minimum. With the revolutionary TIEPRO tying machine Stäubli enables mills to quicken the pace. Its electronic double end detection in combination with the unique auto-reverse function make the machine automatically start a second yarn separating process if a double end was separated, thus without operator invention. The machine is dedicated to standard yarns and ties short (adjustable length) and constant knots allowing easy and rapid drawing-through when restarting the weaving itself. This tying solution is part of the broad range of Stäubli automation solutions for weaving preparation which all share a key critical attribute: They support the production of perfect warps that enhance the downstream high speed weaving process, which leads to greater volumes of first-quality output.

By investing in Stäubli machinery, the weaving mill can expect to benefit from an optimized production process, and the flexibility these solutions offer make them adaptable to the mill’s future projects as well. “Our global and local service teams, our agents, and our spare parts network also support our customers with personalized services,” says Mr. Legler. “They can achieve their goals more easily and master challenging situations,” he adds.