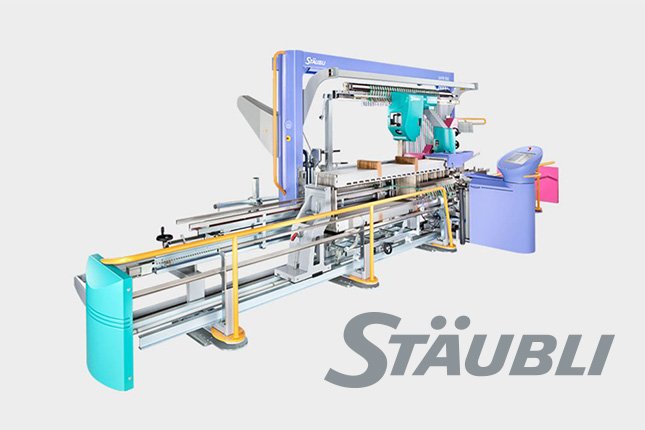

![]() Being unveiled as a world premiere at the ITM, this new machine is perfectly adapted to the needs of the Turkish market. It features the innovative MX PRO module, controlled by NOEMI electronic architecture and the new TC8 controller. This energy-efficient Jacquard installation promises weavers outstanding reliability and ease of use.

Being unveiled as a world premiere at the ITM, this new machine is perfectly adapted to the needs of the Turkish market. It features the innovative MX PRO module, controlled by NOEMI electronic architecture and the new TC8 controller. This energy-efficient Jacquard installation promises weavers outstanding reliability and ease of use.

Visitors to the booth will see a wide range of machines and systems for efficient weaving preparation, frame and Jacquard weaving, and carpet weaving. We will be glad to explain many advantages that Stäubli solutions can provide for your textile mill, such as:

• Quality output with highest weaving speeds using the S3260 rotary dobby with 16 frames and dedicated zero-maintenance transmission.

• Smooth weaving start-up thanks to the TIEPRO warp tying machine offering easy use and ensuring perfectly tied warps.

• Efficient style changes with the SAFIR S60 automatic drawing-in machine.

• Reduced downtime in selvedge weaving when changing the fabric width with the N4L Jacquard machine.

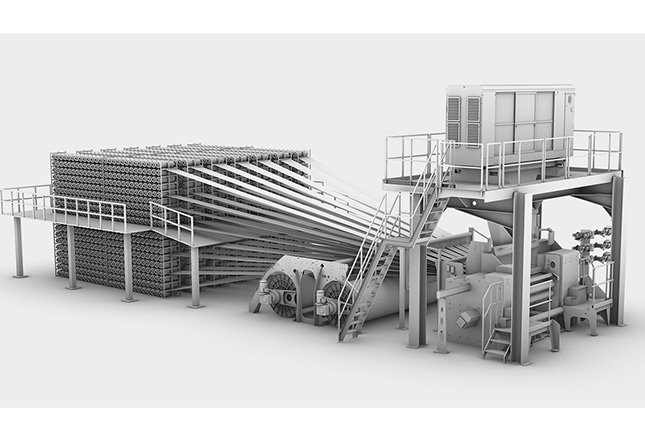

Solutions for weaving technical fabrics

From June 21 – 24, trade fair visitors in Frankfurt a.M., Germany are welcome to meet Stäubli specialists for technical textile weaving at Booth D89 / Hall 12.0. Weavers and R&D engineers from many industries will find out how Stäubli systems and solutions master every requirement for the production of technical fabrics for constantly expanding areas of application.

Reinforcing fabrics for lightweight applications, heavy industrial textiles, 3D carbon fabrics or ceramic multilayers, and more – all of these applications require specialized, fully reliable, high-performance production solutions throughout the entire manufacturing process.

Stäubli provides progressive weaving mills around the world with such solutions: the Stäubli TF weaving system, a broad range of shed formation machinery including cam motions, electronic rotary dobbies, and Jacquard machines, and automation solutions for efficient weaving preparation. A few example applications, including OPW airbags, woven on Stäubli machinery and systems. Are you dealing with the challenging world of technical textiles? You’re welcome to discuss your thoughts and needs with our team. Stäubli looks forward to meeting you and proposing a perfectly tailored solution for your future projects with technical textiles.