Tecnorama is specialized in designing and producing mechatronic systems for the automatic handling of chemicals and dyestuffs used in the

dyeing processes of all textile materials. Focused on automation, Tecnorama aims to increase reproducibility between laboratory and production recipes and optimize the dyeing processes.

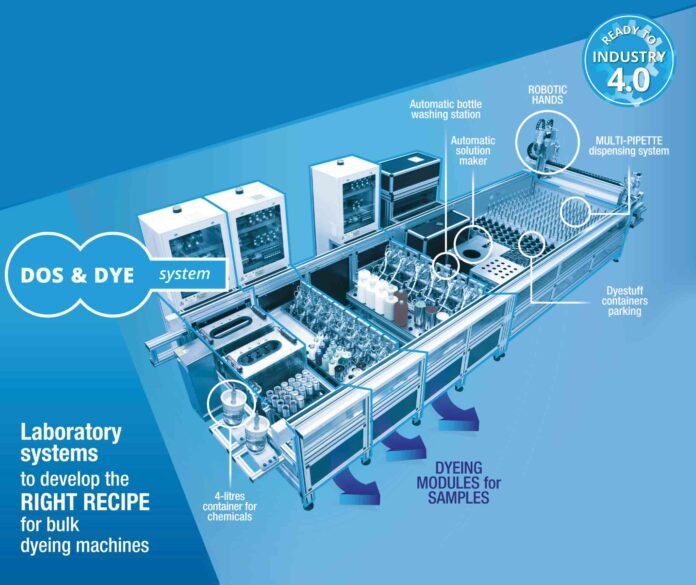

DOS&DYE® is an automatic laboratory dosing and dyeing system with a great worldwide reputation. It is the first and the only one system

developing the right recipe for bulk dyeing machines, in order to avoid correction and re-dyeing in production with considerable time and resource savings. Composed of a Dosorama dispensing machine and one or more robotized dyeing modules, the DOS&DYE® works independently for 24 hours a day and 7 days a week.

It automatically performs the whole dye-bath process without any operator intervention and matches the features complying with Industry 4.0. The DOS&DYE® system has been adopted by leading textile companies around the world for its accuracy, efficiency and reliability.

Tecnorama is committed to provide the textile industry with state-of-the-art automation technology. These innovations will enable the textile

companies to optimize productivity, minimize wastes and reduce labour costs but maintaining high quality and perfect reproducibility. The

DOS&DYE® system has already revolutionized the dye-house working method. With its innovative and automated technologies, Tecnorama

has been a leader in the sector for many years.

Tecnorama presented its latest innovations for laboratory, to be fully integrated in the DOS&DYE® system, including:

DOSORAMA MASTER: the best performing dispensing machine, evolution of the DOSORAMA WS.

DYRAMA 4R/1000: yarn dyeing module with 1 kg capacity.

ROTODYRAMA 6R/20: dyeing module for small pieces of fabric and knit.

DOSORAMA CLEVER: the fully automatic dispensing machine with multi-pipette monoplunger system combined to a SHAKERAMA dyeing module.

The ASV – VERTICAL AUTOSTORAGE and the APV – VERTICAL AUTOPARK are also new solutions developed for bulk highlighted at ITMA.