![]() Today’s textile markets are highly competitive throughout the entire value chain from fiber to fabric. Customers expect unique products of the right quality and free from unacceptable defects. Fabric producers need to manufacture economically with the best possible use of resources. The significant challenges require comprehensive management strategies – and fabric inspection.

Today’s textile markets are highly competitive throughout the entire value chain from fiber to fabric. Customers expect unique products of the right quality and free from unacceptable defects. Fabric producers need to manufacture economically with the best possible use of resources. The significant challenges require comprehensive management strategies – and fabric inspection.

In the classic fabric production process, manual inspection and lab testing are time-consuming operations that need to be optimized with automated solutions. Adding automation to the process will reduce production costs and satisfy customers by delivering 100% inspected fabrics. The advantages of data generated at automated fabric inspection bring the added benefit of helping customers prepare for the future. The Uster EVS Fabriq Vision is an excellent example of proof

The fabric quality assurance system

Fabric producers need to guarantee the reliable quality, which requires a consistently high defect detection rate. Uster EVS Fabriq Vision ensures this is achieved by using automated control during intermediate and final inspection, removing the need for costly manual inspection. The system’s ability to capture any visible defects optimizes fabric yield and prevents claims.

Real-time process monitoring detects, records and locates all defects in every roll of fabric. FabriqVision can capture any visible defect at the line running speeds. It can be used in various positions on most manufacturers’ machines. Inspection is objective, accurate and consistent. The automatically generated defect map serves as the basis for improved fabric quality, leading to maximum fabric yield for various applications.

The key to consistent quality is optimized grading efficiency. Uster EVS Fabriq Vision provides real-time alerts for operators, showing all defects and automatically creating roll inspection charts. All detected faults are collected in an album for review. Here the operator can quickly mark faults and select those which can be deleted. Users can set their own quality standards for different types of fabric and increase the efficiency of the grading process.

Data is the key to a bright future

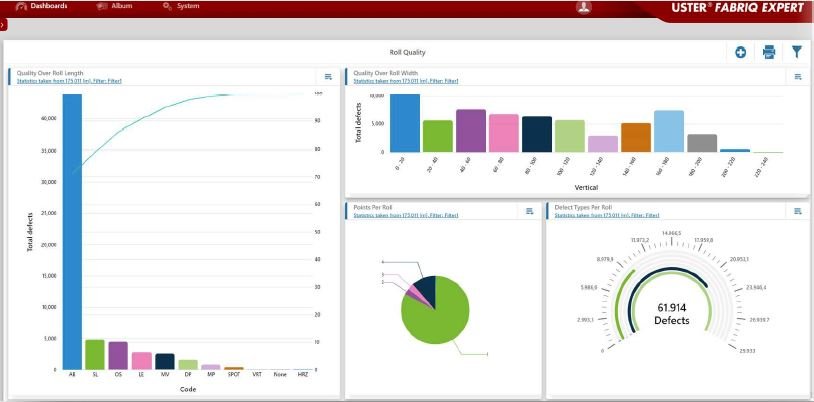

Uster Fabriq Expert is a real-time quality analysis system providing fully-customizable quality analysis tools. Information on the process and product quality, based on data from each fabric roll inspected with the Fabriq Vision or another Uster fabric inspection system, is well displayed on the PC screen. Uster Fabriq Expert helps managers and operators optimize product and process quality without needing an additional quality reporting routine.

Yield – what finally counts

After final inspection, the fabric will often be cut into smaller rolls, which will be delivered to various customers. Optimized cut control (OCC system) provides a tool for automated cut optimization and additional components that can be installed on any existing debatching or cutting line. Upgraded process efficiency comes with clever software, and the cut optimization software automatically identifies the correct cutting position to achieve maximum fabric yield according to quality requirements. Invisible synchronization marks are – also automatically – applied and indicate the position of defects and cut positions in a roll, so these are always under control, allowing the cutting table to run at the maximum possible speed for maximized fabric yield.