– Axel Pieper, CEO, Brückner Trockentechnik

Strauch: Gentlemen, in the daily press I get sometimes the impression that I4.0 / digitization is an end in itself. Mr. Pieper, in textile finishing, energy consumption plays a crucial role. Can I4.0-solutions help to reduce energy costs?

Pieper: Brückner has developed an intelligent machine assistance system that monitors the settings of the entire system in the background. Deviations from default values are immediately signaled to the machine operator and stored in the production history logbook. A new simulation tool helps the machine operator to get the highest possible productivity and/or energy savings out of the system. Maintenance and spare part suggestions are displayed preventively after a certain interval. Upcoming maintenance tasks are comprehensively visualized for the maintenance department and can even be retrieved from mobile devices.

Pieper: Brückner has developed an intelligent machine assistance system that monitors the settings of the entire system in the background. Deviations from default values are immediately signaled to the machine operator and stored in the production history logbook. A new simulation tool helps the machine operator to get the highest possible productivity and/or energy savings out of the system. Maintenance and spare part suggestions are displayed preventively after a certain interval. Upcoming maintenance tasks are comprehensively visualized for the maintenance department and can even be retrieved from mobile devices.

Strauch: How can a finishing company realize savings potentials with this solution?

Pieper: During production, a production assistance system helps the operator to decide which parameters need to be adjusted to make the system even more energy-efficient and productive. Optimized recipes can be stored for future processes and are therefore very easy to reproduce. At the customer’s request, we can also connect his system to a higher-level control station system. This allows recipe data to be researched in a central data base and to be shared with other users. This new intelligent assistance system in combination with the simulation tool allows productivity increases of up to 40%. Energy consumption can be reduced by up to 30% with these systems.

– Maximilian Kürig, Managing Director, KM.ON, a software start-up company of Karl Mayer

Strauch: Let’s go a step forward in the textile chain. Industry 4.0. is also an issue in fabric production. Mr. Kürig, at ITMA ASIA 2018 Karl Mayer launched its own digital brand, KM.ON. What is new in the associated digital solutions portfolio with regard to production?

Kürig: KM.ON’s range of features has been extended considerably. A good example from Karl Mayer is a new digital tool that combines a PDA system with a ticket system to enable any disruptions in production to be managed efficiently. The relevant information can be input easily and quickly at the machine and forwarded to the appropriate location in real time. Any problems can be dealt with quickly, and the root cause can be tackled rapidly by displaying the relevant sequence.

Kürig: KM.ON’s range of features has been extended considerably. A good example from Karl Mayer is a new digital tool that combines a PDA system with a ticket system to enable any disruptions in production to be managed efficiently. The relevant information can be input easily and quickly at the machine and forwarded to the appropriate location in real time. Any problems can be dealt with quickly, and the root cause can be tackled rapidly by displaying the relevant sequence.

Strauch: What does this tool mean for the machine operator? Is it an operator friendly technology?

Kürig: This system is very easy to operate, which means that this new development can be used immediately.

– Rainer Mestermann, Managing Director, Mahlo

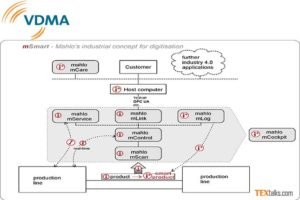

Strauch: Let’s stay in the finishing process. Mr. Mestermann, company Mahlo develops and produces measurement and control equipment for the textile and nonwoven industry. A basic idea of Industry 4.0 is collecting and processing data for better production results. How is Mahlo addressing this issue?

Mestermann: A new platform from Mahlo realizes these ideas of industry 4.0 with digital technologies. In the digitization concept for all Mahlo products, the functionalities are grouped, optimized and standardized as “services”. This results in modular hardware and software function blocks that can also be retrofitted. There are modules e.g. for the acquisition and processing of measured values, for control tasks or for the long-term archiving, data logging and analysis.

Mestermann: A new platform from Mahlo realizes these ideas of industry 4.0 with digital technologies. In the digitization concept for all Mahlo products, the functionalities are grouped, optimized and standardized as “services”. This results in modular hardware and software function blocks that can also be retrofitted. There are modules e.g. for the acquisition and processing of measured values, for control tasks or for the long-term archiving, data logging and analysis.

Strauch: Why should manufacturers and finishers of textile fabrics invest in your solutions?

Mestermann: Our new platform makes it easier for customers to use data in a meaningful manner to optimize their processes. Networking of Mahlo devices with each other and with other systems ensures consistent data exchange and enables the bundling of information as a basis for process improvement. Higher machine availability through remote maintenance via better product quality by adaptive control or flexible data analysis as the basis for better decisions provide immediate monetary benefits.

Strauch: Can you quantify the benefits, please?

Mestermann: One example is the control module in our weft straighteners. Together with a renowned university, the distortion control was revised and digitized. Optimized hardware and software resulted in a faster and more efficient controller. Evaluations confirmed by customers prove that the control module regulates 20% faster and more precisely than before. Better straightening results reduce the production of second-choice goods and the need to pass the same fabric through the stenter several times.

– Dr. Janpeter Horn, CEO, Herzog

– Dr. Janpeter Horn, CEO, Herzog

Strauch: Dr. Horn, Herzog is producing braiding machines. What is your latest I4.0 product and what is your approach?

Dr. Horn: An additional module for Herzog machines, an app-box, with which Industry 4.0 scenarios can be realised without employing software teams or starting big Industry 4.0 projects. This technology is an app-based one. Apps can be downloaded and installed easily.

Strauch: How do customers benefit from this?

Dr. Horn: The customer can easily access the data of Herzog machines, e.g. on a PLC (Programmable Logic Controller). The data can be visualised on dashboards created by the customer on terminals or others. The data can be processed, e.g. by creating key figures, alarms or analyzation. Alarms and information could be transferred by e-mail, messengers. Furthermore, the data can be linked to order from pps systems or transferred to the machines – if the customer decides to go this way.

Strauch: Can you quantify the benefit?

Dr. Horn: No formation of software teams outside machines. New applications could be created easily. No additional software.

Strauch: What is really new at this solution?

Dr. Horn: It is the result of a three-year research project. Various innovations have been implemented: The use of cloud technologies on the shop floor; open source technologies for inexpensive apps; no internet connection is necessary. The main advantage however is the “one-click” installation of apps which have been applicable only for smartphones and tablets. The apps are installed in a so-called box outside the machines.

Dr. Horn: It is the result of a three-year research project. Various innovations have been implemented: The use of cloud technologies on the shop floor; open source technologies for inexpensive apps; no internet connection is necessary. The main advantage however is the “one-click” installation of apps which have been applicable only for smartphones and tablets. The apps are installed in a so-called box outside the machines.