USTER® SENTINEL now offers more than just end-break detection system. For ring spinning optimization it is a comprehensive system providing quality, efficiency and productivity benefits. Using USTER® TESTER 6, data integration can now be performed through Total Testing CenterTM which provides the spinners with quality overview of all the processes in the mill to enhance production management. USTER® ROVING STOP further enhances the economic advantages by reducing the waste through immediate end break detection and ceasing the roving feed.

Optimized yarn production key is the bobbin build-up report by USTER® SENTINEL. The end breaks detection provides with basic platform which when combined with the USTER® ROVING STOP leads to total control of end breaks. The waste reduction makes the raw material usage more effective. According to the calculations based on current spinning conditions, 1% raw material is saved by reducing pneumafil waste to 70%.

Top quality productivity

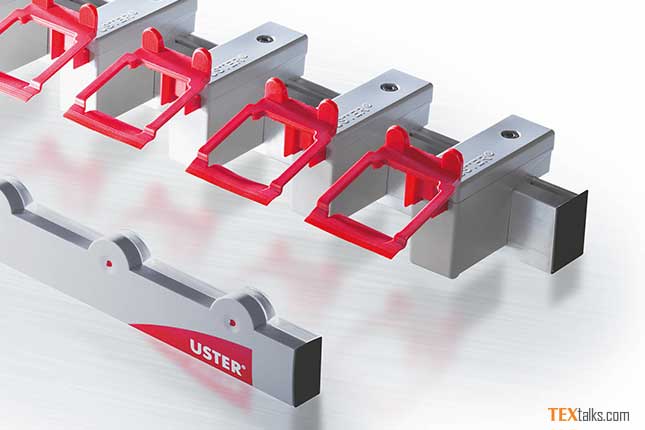

USTER® SENTINEL used with USTER® ROVING STOP provides improved productivity and lessens the quality problems risk in ring spinning by control in waste material and fiber negatively affecting the neighboring spindles as well as the entire machine. Reduced lapping prevents roller overloads and can extend the service life of spinning parts by 20% which includes cots, cylinders and aprons.

Furthermore, the compact shape and unique designs saves time, speeds up the processes and avoids raw material wastage through complete separation of the process.

Visual clarity directs the exact breakage reasons which makes optimization easy. Fast overview of production performance, energy consumption and laboratory data is available in real time. The expert system also guides the mills towards profitable optimization.

Profitability goals

USTER’s ring spinning optimization system maximizes the profitability ratio by controlling and monitoring yarn manufacturing and spindles productivity and provides better optimization of machine performance as well as the entire process.