Denim production is one of the most water-intensive processes in the world. Dyeing cotton warp yarns with Indigo in continuous dyeing machines consumes a large amount of water and energy during pre-washing and post-washing treatment, leading to high wastewater pollution.

The Indigo dyeing machine consists of a pre-treatment box and 2 to 4 washing boxes. Before dyeing, the pre-wash boxes aim to remove caustic soda and other impurities completely from the substrate. The impregnation in the dyebaths with the reduced Indigo and the oxidation in the air should be repeated many times to obtain the desired shade. Finally, the dyed cotton warps are subjected to post-treatment with cold or hot water in 3 to 5 washing boxes to improve color fastness.

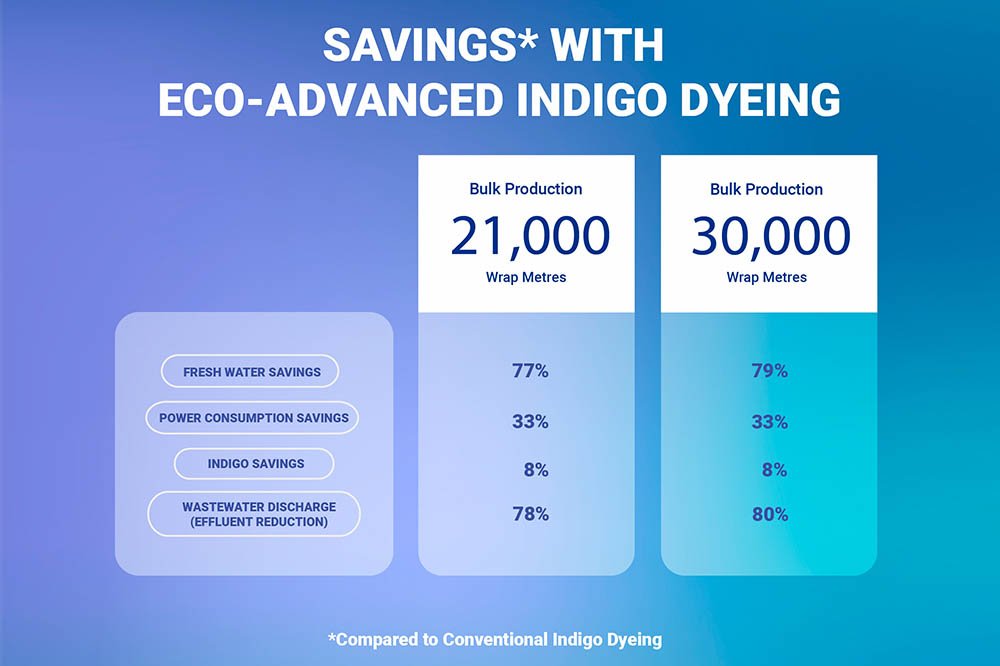

Customer Case Study:

Independent customer case studies have shown us the positive environmental impact of Eco-Advanced Indigo Dyeing (EAID) compared to conventional Indigo dyeing:

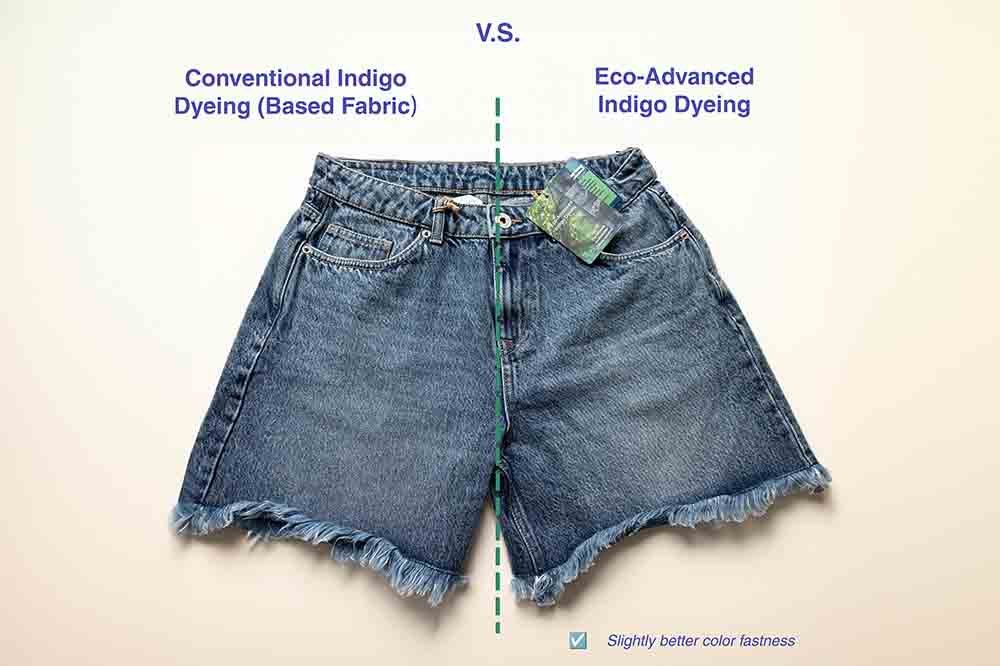

The color fastness of Eco-Advanced Indigo dyeing was also compared to conventional Indigo dyeing – which shows a similar or slightly better color fastness.

Building Blocks of Eco-Advanced Indigo Dyeing:

The Eco-Advanced Indigo Dyeing is based on DyStar® Indigo 40% Solution and Lava® Fix FFA Eco, which have the following features:

Benefits of Eco-Advanced Indigo Dyeing:

Benefits of Eco-Advanced Indigo Dyeing:

• Ecological and sustainable process

• Immense savings in water, energy and chemicals

– Up to 90 % Water saving

– Up to 30 % Less energy

– Up to 10 % Less Indigo

• Strong effluent load reduction of up to 85%

• Improved ring dyeing effect

• Laser friendly process

• Improved quality of the Denim fabrics

• Supporting zero discharge sustainable solution

DyStar’s Eco-Advanced Indigo Dyeing concept is developed to help denim customers achieve better quality consistency while reducing wastewater treatment in the effluent. Its products further support customers on their sustainability journey towards a cleaner and more cost-effective production environment, while ensuring that quality is not compromised.

Trademark statement:

DyStar and Lava are registered trademarks of DyStar Colours Distribution GmbH, DE.

bluesign is registered trademark of bluesign technologies ag, 9014, St. Gallen, CH.