Ferraro Spa, a leading company that has been operating for over 70 years in the textile finishing sector, both knitted and woven, with thousands of plants all over the world, is well aware that competitiveness must be necessarily achieved through innovation and environmental sustainability.

This is the only way to remain a market leader in a highly competitive international context.

The theme has become a guiding element of the company’s vision and an integral part of our daily lives, requiring us to adopt circular economy processes, reduce emissions, reduce energy from non-renewable sources, and ‘greening’ both production processes and products.

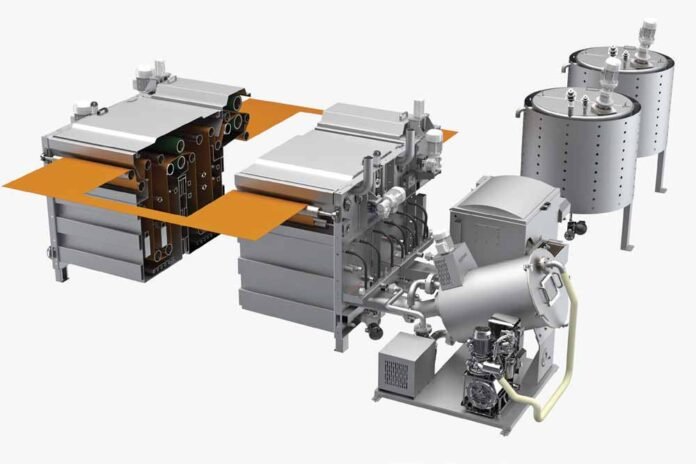

In the last year alone, Ferraro has launched a series of innovations aimed at innovating production processes with more efficient and cost-saving solutions. The latest modernization in chronological order is FerrSonic, a scouring and oil removal system for synthetic and mixed fabrics, especially those containing elastomer. Unlike the traditional removal process carried out with a jet dyeing machine, where a large amount of water is used (typically 20 to 45 litres/kg of fabric), FerrSonic achieves the remarkable result of 3-4 litres/Kg, about ten times less.

This is possible because FerrSonic is equipped with a self-cleaning filter which enables the washing liquid to be completely recycled.

In addition to water consumption, it must be considered that in the traditional jet dyeing process, scouring is an ‘off-line’ operation that takes a long time and also involves significant electricity consumption.

FerrSonic, which is normally installed in front of a stenter (in combination with a squeezing padder), allows continuous in-line washing that has no time impact and much lower electrical consumption. Moreover, the use of customized ultrasound technology, specifically designed for continuous washing processes such as scouring, boosts the cleaning power of the water used during the washing treatment. The result of this application allows the consistent reduction of chemicals (up to 65%!) and up to 30% to 50% less water with a shorter washing time.

Besides the above significant values, the use of the cavitation energy requires a maximum of 65 C° for the water instead common 90/95 C° commonly used. The result is a consistent reduction of energy consumption up to 50% less and contributes to cutting operating costs as well as lowering CO2 emissions.

Once the high efficiency and performance of ultrasound technology in removing oils, waxes, fats, gums, fluffs, etc… from the fabric, impurities that create serious problems in all the processing steps such as heat setting on the stenter, it is very important to keep the water batch constantly clean avoiding the dirty parts to be picked up by running fabric and transported to next machine section creating huge contamination. For this purpose, Ferraro has developed SCS (Self Cleaning Strainer) an innovative and patented continuous filtering system with vacuum technology, capable of cleaning the whole batch of the washing tank every single minute.