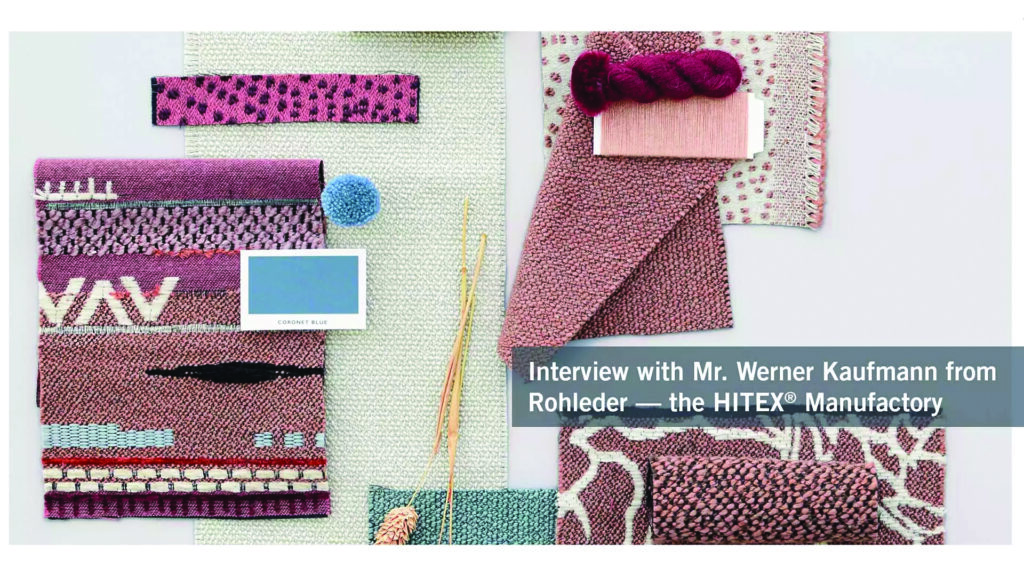

![]() In an interview with Loepfe, Werner Kaufmann of Rohleder Germany, describes why a small Loepfe product is part of the company’s success.

In an interview with Loepfe, Werner Kaufmann of Rohleder Germany, describes why a small Loepfe product is part of the company’s success.

Loepfe since its establishment in 1955 by the brothers Helmut and Erich Loepfe, has been the pacesetter for innovation in textile quality control.

They have established themselves in the field of optical yarn clearers with pioneering achievements. Today, Loepfe is considered world-wide as the specialist for integral quality control systems. Fifty percent of the world-wide staple yarn production are monitored by Loepfe yarn clearers.

On the other side, Rohleder the HITEX® Manufactory is much more than a weaving mill. At their plant in Konradsreuth Germany, they have been producing designer fabrics of the highest level of quality, comfort, and durability since 1946. They manufacture sophisticated upholstery and furnishing fabrics of the highest quality in a wide range of colours, textures and patterns, implementing specialist knowledge of the highest level. Loepfe considers itself fortunate to have one of the most successful weaving mills in Europe as a customer. As a result, the weaving machines specially modified for Rohleder have been equipped with the WeftMaster CUT-iT thermal fabric cutter since mid-2019.

Loepfe: Rohleder offers a wide variety of high quality fabrics. Whether these are velvets or epinglé, furnishings or flat wovens, dobby or jacquard, Rohleder offers a seemingly unlimited choice of materials, textures, colors and patterns. What challenges does this pose for daily production?

Werner Kaufmann: We have very flexible employees with high-quality awareness – there would be no other way. Of course, our extensive design and R&D competence is also an important building block, in addition to the constant maintenance and renewal of our machinery.

Loepfe: Alongside the distinctive design requirements at Rohleder, the quality concept is a mainstay running through all process steps. Why is quality so important to you?

Werner Kaufmann: For us as a company with production facilities in Germany, quality is a natural feature.

Loepfe: You rely on modern technologies and machines and components customized especially for Rohleder, Why did you choose a product from Loepfe for the fabric separation?

Werner Kaufmann: The hot wire cutters prevent unwanted problems in our thermal-mechanical finishing process during further processing. The CUT-iT system gives the selvedge more stability, which means we produce significantly less second choice.

Loepfe: How many CUT-iT systems are in use throughout your production?

Werner Kaufmann: Six, possibly seven soon, all other machines run with the machine manufacturers cutting system.