From earth with love, air, and less water

Coming from earth – air and water will soon follow – cotton is, par excellence, the king of natural fibers. That is because of its main feature, a key concept in the twenty-first century: versatility. Besides, no synthetic or artificial fiber is able to replace cotton as it happens with other natural fibers. Furthermore, it allows a very competitive processing and, with great satisfaction for the textile industry R&D, new sources of inspiration. And what about cotton applications? From home textiles, an industry always asking for a variety of fabrics that are aesthetically perfect as well as high-performing – let’s take a terry world tour to get an idea – to the field of medicine where cotton shows all its unique feature.

Biancalani Textile Machinery becomes part of that processing from the moment when cotton is neither “just” a flower nor a fiber anymore, but it has been turned into a fabric by loom working – a process that is being studied in Italy and specifically in Prato by experts and researchers from all over the world. After weaving, the aim is to improve the already excellent cotton features as much as possible by acting at different levels with different machines, always in the most sustainable way.

First of all, it is mandatory to go ahead with processes aimed at preparing the fabric for dyeing or printing, those ones that Biancalani machines can take care of in continuous and in an innovative way, like de-sizing or eco-bleaching. Subsequently, after-print and after dyeing processes are necessary and that is when Biancalani machinery can definitely make the difference thanks to their incredible water-saving potential.

It is during the following fabric treatments that Biancalani machinery manages to further enhance the cotton features, as in the case of washing with natural enzymes which removes the pilling from short cotton fibers and can also be used to give them a perfect peach-skin effect. Or, while interacting with previous dyeing and printing processes, to boost the fabric aesthetics, getting to effects such as delavé, all of them in continuous. For more, see some of the finishing options by AQUARIA®.

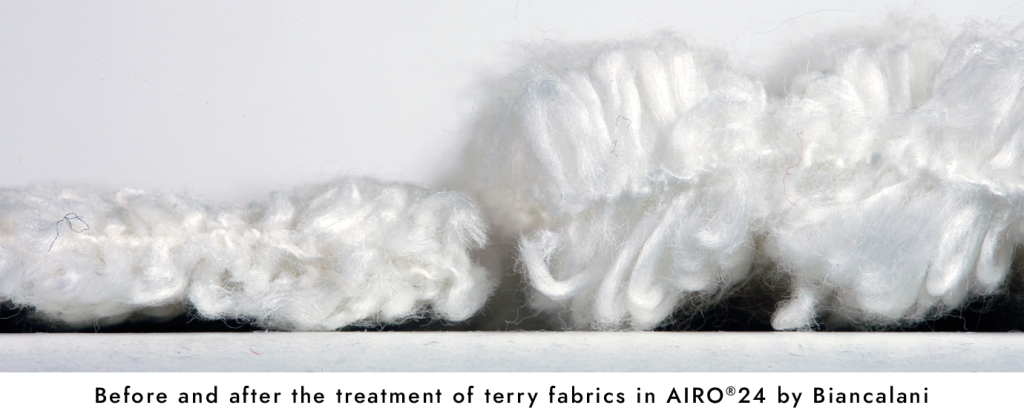

Among other finishing precious results, we can highlight the ones coming from processes that act deeply on cotton fiber structure, such as mechanical softening – does AIRO® HAND effect by AIRO®24 ring any bell? The mechanical action reduces the usage of chemical products drastically or in some cases makes chemical products totally unnecessary and ensures a longer-lasting effect, both of which earn it an indispensable characteristic: sustainability. And here comes the air: the machinery AQUARIA® and AIRO®24 from Biancalani use air to move and handle the fabric during a fully open-width process so that it all becomes completely safe, and at the same time washing and drying processes are more efficient and the softness unmistakable. In fact, when used in the right way, as in Biancalani machines, air can definitely be the most valuable ally. For example, by pushing water with air, the action will be much more intense and the water needed far less. In any treatment of cotton and blends.

Thus, it is time to talk about water. Let’s take the example of continuous eco-bleaching carried out in AQUARIA®: non-polluting products make it possible to recycle all of the processing water, for an almostzero water dispersion. As water consumption is one of the problems of cotton processing, one of the companies’ main aim is precisely to reduce it and, as a consequence, cut pollution.

It all comes from earth, air and water. Nature gives us such fantastic fibers as cotton or wool – we will focus on that soon – and asks us, today more than ever, to treat them in a sustainable way, enhancing their already incredible characteristics, making the best out of its gifts. Thanks to Biancalani’s Research and Development department, we are able to answer its call.