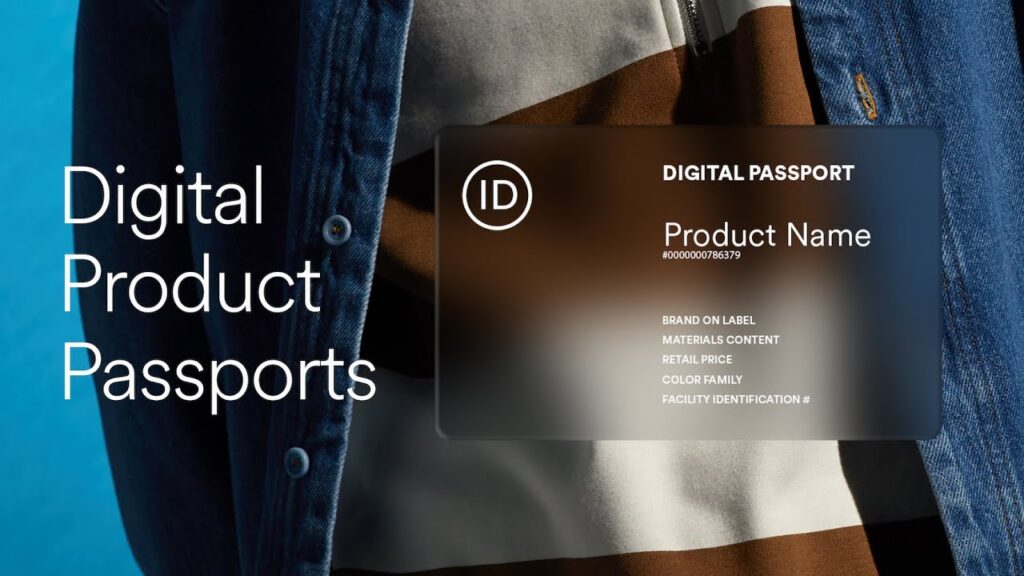

The EU Strategy for Sustainable and Circular Textiles has set out an ambition for all textile products available on the EU market to be long-life and recyclable by 2030. With the introduction of the Circular Economy Action plan in 2020, the European Commission aimed to consider the entire life cycle of products, from production to end-of-life disposal, covering all the processes relating to materials sourcing, production, and supply chain. However, the lack of information on the characteristics of a product (such as its contents, production methods, or life cycle) was and is a barrier to circular economy strategies. As part of the proposal for an Ecodesign for Sustainable Products Regulation (ESPR), the Digital Product Passport (DPP) was introduced in 2022 with a focus on enhancing the traceability of products and allowing consumers and manufacturers to access all the information concerning a specific product. It can provide information on a product’s origin, composition, repair, disassembly options, and how the various components can be recycled.

Digital solutions are a driving force to a more sustainable economy; data and technology can enhance the much-needed transparency in the sector that citizens seek. Currently, our linear economy lacks widely available information about the distributor, the components, their origin, and the recycler. DPP can enable information monitoring and proper management of a product and its life cycle. More directly, DPP will empower citizens in their daily choices, giving them more clarity on how and where a certain product is made. DDP will ultimately increase transparency, accountability, and traceability for each actor in the value chain. In addition, the DPP can have a wider positive application that goes beyond the circular economy. Because of increased transparency and knowledge, the digital product passport can include and provide data on GHG emissions, certificates, and other criteria important for reporting and auditing processes for customers, investors, or stakeholders. This also has the potential to advance the industry’s climate neutrality goals. Thus, DPP could be essential for the sustainable drive in 2023 and onwards for the textile sector.

Further this week, Avgol®, a global leader in the manufacture of high-performance nonwoven fabric solutions, has announced that this month’s FILTECH exhibition in Germany showcases its latest developments in using Algaeing™’s patented algae bio-based formulations for colorants and fibers. Algaeing’s technologies utilize various sustainably sourced, vertically farmed algae species to produce many appealing colors, many of which replicate the colors used in nonwoven fabrics today.

Further this week, Freudenberg – a global technology group dedicated to excellence in technical solutions – has launched the apparel industry’s first product range that uses a biodegradable adhesive in cotton interlinings. The adhesive in this advanced and new product range allows the interlinings to be biodegradable and represents a major advance for the apparel industry and environmental sustainability. According to the company, growing concerns about sustainability in the apparel industry have led to major shifts in textiles and apparel cultivation, manufacturing, and end-of-life management.

Therefore, the interlining range offers excellent biodegradability and does not harm plants or animals. Approved by the highly-respected Hohenstein Laboratories (based on soil burial test using parts of DIN EN ISO 11721-2:2003 and EN ISO 846), these fusible interlinings have an expected 90% degradation in approximately 15-20 months (based on different weights of cotton base materials) – results of laboratory tests from June 2021 to June 2022. Beyond biodegradability and non-toxicity, these new interlinings are also energy-saving, as they can be fused at 127°C rather than the standard 143°C. Despite a lower fusing temperature, these STANDARD 100 by OEKO-TEX® certified interlinings retain washability at up to 40°C, are dry cleaner safe, and apply to various garment parts (such as collars, cuffs, and plackets for men’s shirts and ladies’ blouses).

Further this week, India has committed to reducing the emissions intensity of its gross domestic product (GDP) by 45% by 2030 and reaching net zero by 2070. India’s long-term low-carbon development strategy rests on seven key transitions to the low-carbon development pathway. The strategy notes that alongside the imperative of development, there is a need to ensure energy security, based both on the expansion of non-fossil fuel sources for power generation and rational utilization of fossil fuel resources, he was quoted as saying in an official release.

Further this week, the Indian Institute of Technology (IIT), Ropar has developed a green technology called air nano-bubble, reducing the water used in the textile sector. The institute has claimed that the technology can reduce water use by up to 90%. As per a rough estimate, 200-250 liters of water are required to process 1 kg of cotton.

Further this week, Vietnam’s industry insiders and policymakers have shown interest that the country must start monitoring and issuing carbon certificates to exporters and retailers in response to the European Union’s (EU) recently-passed carbon levy. Instead of buying the EU’s carbon certificate, domestic businesses could take steps to reduce their carbon footprints during production, experts feel.

Further, in sustainability, Asian Development Bank’s latest report highlighted that greener trade and investment are crucial to tackling climate change in Asia and the Pacific and will require regional governments to work together more closely. The report also highlighted that the region’s production-related carbon dioxide emissions have almost tripled between 1995 and 2019, largely due to the region’s economic growth and industrialization to meet both domestic and export demand. Asia and the Pacific are warming faster than any other part of the world, and almost 40% of the world’s disasters occur in the region, affecting over 70% of the people affected by disasters globally.