Oritain at a glance

• Global leader in product origin verification

• Comprehensive product mapping includes complete coverage of all core cotton producing countries

• Strengthens supplier credibility, compliance and market access

• Integrates seamlessly without disruption

• Trusted by global brands and regulators

• Accepted as evidence by U.S. and E.U. regulators

Premium buyers in North America and Europe now expect independent verification of raw material origins. What started as regulatory compliance has become a competitive differentiator. Manufacturers who can prove their supply chain claims with scientific data are securing larger contracts, expanding into new markets, and commanding better terms.

Oritain, a global leader in origin verification, applies forensic science and data to verify the origin of products and raw materials. The innovative company helps the world’s leading brands, manufacturers, and suppliers comply with regulations and protect their reputations.

The value of forensic verification for manufacturers

New business deals and contract renewals

When manufacturers position themselves as verified, trusted partners, they gain a commercial advantage in new business negotiations or expanding business with current ones, as brands are looking to work with partners who already have verified origin and compliance in place. Demonstrating data and history to potential new and high-value customers can help differentiate a business in competitive situations and gain market share.

Meet customers’ requirements

Buyers are under pressure to prove their own sourcing and are asking suppliers to provide traceability for their tier two and tier three areas to meet forced labour and modern slavery obligations. Oritain’s forensic methodology helps provide assurance of a manufacturer’s supply chain and their partner mills as well through independent, reliable data that satisfies customers’ demands for higher levels of evidence and wins their trust.

Identify problems early and take corrective action

Manufacturers can make smarter business decisions by identifying problems early in their supply chains. For example, verifying inbound yarn helps catch issues before products reach customers. This proactive verification helps avoid any late-stage checks from brands and retailers, where inconsistencies in finished goods can lead to refused orders and stress on relationships.

Reduce risk and protect your business

Oritain provides a robust and scientifically-backed response to whether a product has been sourced ethically and with integrity by verifying origin claims and ensuring no unauthorised cotton was used, protecting against forced labour risks and satisfying regulatory demands under the U.S.’s Uyghur Forced Labor Prevention Act (UFLPA). Oritain’s forensic methodology is accepted by enforcement agencies like U.S. Customs and Border Protection (CBP) which is beneficial for manufacturers exporting into the U.S.

Scientific verification, not just paperwork

Relying on a paperwork trail for traceability comes with risks like falsified or generic documents that may not truly reflect product origin. Oritain’s forensic testing provides a scientific verification of sourcing claims that are independent and separate to information from any supplied documentation. Scientific verification is especially crucial for avoiding rejected shipments, as U.S. Customs uses their own isotopic testing at labs in Savannah, New York City and Los Angeles to assess origin-related risks in the raw sourcing materials of imported goods.

How Oritain’s verification works

Oritain uses forensic chemistry and data science to verify the origin of products using what it calls an “Origin Fingerprint.”

Just like every person has a unique fingerprint, every product carries a specific chemical signature based on where it was grown, reared, or made. This signature is shaped by environmental factors like soil, rainfall, sunlight, altitude, and even windspeed.

Oritain can analyse these chemical signatures in the forms of natural trace element concentrations and stable isotope ratios. Once it has the chemical analyses for a population of samples from a given origin, the company can investigate and interpret these chemical signatures using multivariate statistics and data science.

The combination of these chemical factors specific to a location is called an Origin Fingerprint.

Like a criminal forensics database for human fingerprints, Oritain stores reference Origin Fingerprints for different commodities and origins in a database. An Origin Baseline refers to the specific subset of Origin Fingerprints and accompanying metadata in a database that are specific to a target origin. When a product’s origin needs to be checked against this target, its chemical data is compared against this baseline to confirm whether it resembles the fingerprint of the claimed origin.

The Origin Fingerprint

Every natural product has a unique chemical signature based on its geographic origin.

Oritain calls this the Origin Fingerprint:

• Derived from naturally absorbed isotopes and trace elements (soil, altitude, climate, precipitation).

• Highly resistant to tampering and admissible in court.

• Enables matching products to a source or detecting inconsistencies.

• No additives, no modifications – just science, tested at multiple stages of production.

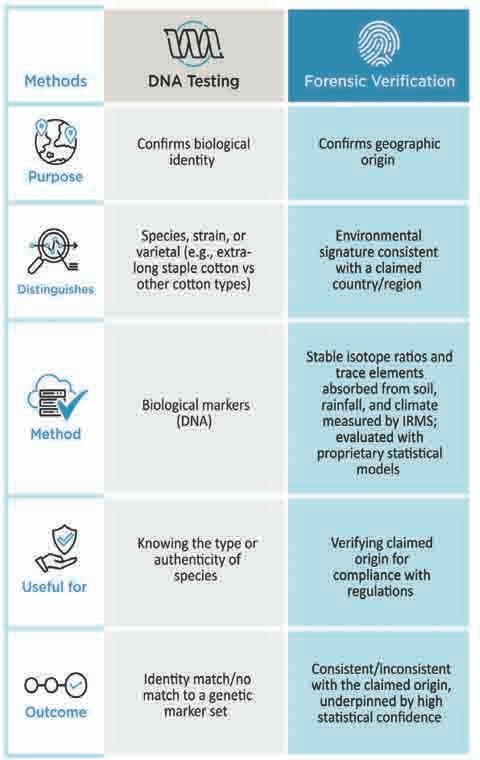

DNA testing is not the same as forensic verification

DNA and isotopes answer different questions. DNA identifies what a product is, isotopic testing answers where the product comes from.

The two methods work on entirely separate principles, and in practice they are complementary.

Traceability without disruption

Oritain’s verification method is designed to seamlessly integrate into existing manufacturing processes, without causing disruptions or delays. The non-invasive sampling techniques can be easily incorporated into standard operating procedures (SOPs) and does not require any changes to existing systems, machinery or production processes.

Samples can be taken at any point in the supply chain – at bale laydown, at the spinner, during fabric production or even from finished goods.

Oritain’s forensic methodology provides scientic evidence of raw material origin, particularly when upstream evidence is limited

Rupert Hodges. Chief Commercial Officer. Oritain shares valuable insights into how origin verification addresses the textile industry’s need for traceability proof.

TEXtalks: Why does proof matter now for the apparel and textile industry?

Rupert Hodges: We’re seeing reputational risk and shipment detentions pushing buyers to seek independent data they can trust. While documentation will always be part of the due diligence process, Oritain’s forensic methodology serves as evidence in lieu of traditional documentation for the origin of raw materials, especially when upstream evidence (for example, spinner’s details) is unavailable. U.S. Customs, for instance, expects more than just documentary evidence; they require an objective way of validating a company’s claims.

TEXtalks: How can manufacturers use forensic verification to strengthen their role as preferred sourcing partners?

Rupert Hodges: Manufacturers already have a lot of inherent traceability in their supply chains and partnering with Oritain provides a way to verify that traceability. Buyers prefer to work with suppliers who are transparent about their supply chains. When a supplier can prove where their materials come from, it basically backups all the great work they are already doing and validates their standards and differentiates them from competitors who only offer paper.

TEXtalks: How can verification reduce risk and give buyers more confidence to place more orders?

Rupert Hodges: When buyers know that raw materials have been independently verified, they don’t have to second-guess their decisions. We regularly see companies who have an ongoing risk mitigation program avoid supplier misconduct and demonstrate to governments and buyers alike that they are exercising reasonable care. That assurance makes it easier for buyers to grow volumes with confidence.

TEXtalks: How is Oritain better than other isotopic testing providers?

Rupert Hodges: Not all isotopic testing is created equal. Many providers operate with limited reference databases, sometimes relying on tertiary samples or inaccessible regions. Oritain’s methodology is built on an extensive, rigorously maintained database of primary samples and proprietary scientific protocols that ensure highly defensible results. When it comes to regulatory and due diligence needs, only high-confidence, validated origin data will withstand scrutiny. Lower confidence rates are simply inadequate for critical compliance requirements and fail to provide meaningful assurance.

TEXtalks: Is origin verification only required by the U.S., or is demand growing in other markets as well?

Rupert Hodges: The U.S. has led with the UFLPA, but it’s not the only market moving. Canada has added new rules under their forced labour law, Mexico has published new regulations, and the EU has introduced laws like the Deforestation Regulation (EUDR) and the Digital Product Passport (DPP). The UK has its own Transparency in Supply Chains Act and Australia is tightening its due diligence requirements. What we are seeing is origin becoming a global expectation, not a regional one.

TEXtalks: Who are you working with currently, and how are they applying forensic verification in practice?

Rupert Hodges: Oritain works with some of the world’s largest apparel brands and retailers, along with leading mills and manufacturers. They use our forensic verification to comply with forced labour laws, to validate marketing claims, and to mitigate risk. Yunus Textiles, a large vertically integrated mill in Pakistan, uses our verification at multiple touchpoints (from incoming raw materials to finished fabric) which gives them real-time visibility and the ability to provide buyers with verified origin data for every shipment.

TEXtalks: What does Oritain onboarding process typically look like?

Rupert Hodges: Our onboarding is designed to be straightforward and fast. We can typically get partnerships up and running within just a few weeks. The process involves identifying the right sampling points in an existing workflow and establishing verification protocols, all without disrupting current operations.

We offer flexible sampling options to fit client preferences and capabilities. Clients can either submit samples directly through our simple collection process, or we can arrange third-party collection services to handle sampling on their behalf. Either way, they will be generating verified origin data quickly and seamlessly by integrating verification into their standard procedures.