The automotive industry is going through a radical transformation phase, characterized not only by vehicle electrification and autonomous driving but also by a silent revolution in the field of fabric treatments. Technological innovation is redefining quality and sustainability standards in a context where consumers are increasingly aware of environmental impact and vehicle living comfort.

Automotive Market Trends and Impact on Fabrics

The production of electric vehicles is driving new needs in fabric materials. Manufacturers are seeking lighter fabrics to compensate for battery weight while maintaining high standards of durability and comfort. In parallel, the advent of autonomous vehicles is redefining car interiors. Cabins are transforming into true living spaces, requiring fabrics that combine advanced functionality with high living comfort. This trend has led to increased demand for premium fabrics and technologically advanced materials.

The Importance of Specificity in Treatments

Fabric treatments in the automotive industry are divided into two main categories: those necessary for basic performance and those that add distinctive value to the final product. The key to success lies in choosing the appropriate treatment for each specific fabric. In this context, Biancalani Textile Machinery has established itself as an industry leader in ennobling these fabric products, developing innovative solutions already adopted by two of the world’s leading automotive fabric groups.

Specific Solutions for Different Materials

Polyester

Primary objective: fabric stabilization

Focus on: maximizing elasticity

Process: treatment through AIRO®24

Emerging applications: integration with sensors for passenger comfort monitoring

Non-Woven Polyester Microfiber Fabric

Main characteristic: SOFT HAND

Result: comfortable tactile sensation

Technology: AQUARIA® washing process

New functionalities: antimicrobial and self-cleaning properties

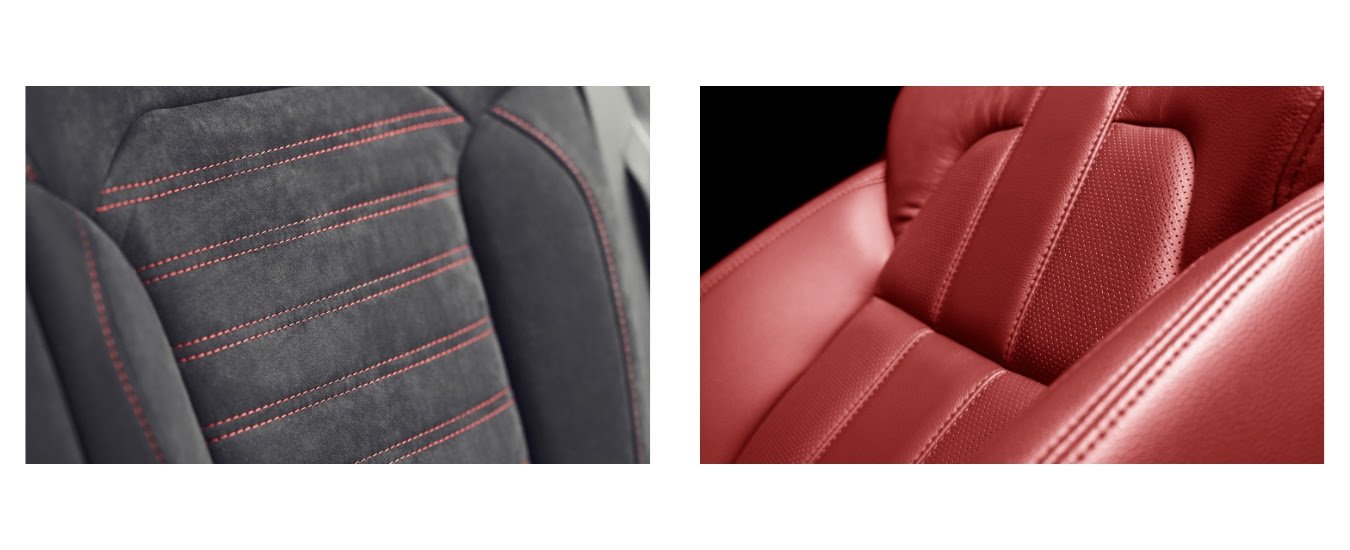

Synthetic Leather

Triple objective:

Increased softness

Improved elasticity

Natural and authentic appearance

Plus: UV resistance and ease of maintenance

Sustainability and Innovation in the Washing Process

AQUARIA® represents the latest frontier in continuous fabric washing process innovation. This revolutionary technology responds to the growing demand for sustainability in the automotive sector, where manufacturers are increasingly committed to reducing the environmental footprint of the entire production chain.

AQUARIA® Advantages

Overcomes limitations of traditional methods

Eliminates the need for chemical solvents

Significantly reduces water consumption

Combines the effectiveness of traditional treatments with modern sustainability

Internationally recognized environmental certification “CLIMA Certified”

The Role of Research and Development in the Current Context

Biancalani’s R&D department has developed this innovative solution in response to current challenges in the automotive industry, including:

The need for lighter materials for electric vehicles

Increased demand for smart fabrics for autonomous vehicles

The need for more sustainable production processes

Demand for materials with advanced properties (antibacterial, self-cleaning, etc.)

Future Prospects

The automotive textile treatment field will continue to evolve, driven by:

Integration of smart technologies in fabrics

Development of bio-based materials

Optimization of production processes from a circular economy perspective

Increasingly customized vehicle interiors

This innovative approach represents a third way in automotive fabric treatment, overcoming the limitations of both traditional high-water consumption systems and lines using chemical solvents, positioning itself as an ideal solution for future challenges in the automotive industry.