Since 1958, LAIP’s productive strength, a desire for constant renewal, acceptance of new market challenges, new technologies, and the ability to have a constant dialogue with customers, not only before and during the sale but also after the sale is the reason behind success over the years. Driven by the desire for the best performance, which is not only technical, the company complied with the new business languages, guaranteeing competence and speed in answering the many requests of customers, especially to those customers who look to LAIP for a personalized response to their needs for industrial dyeing.

198 HT, the highly demanded machine for tow – packages, and fiber dyeing, allows the same liquor ratio to be maintained even with partial loads! BID, (Bobbins Injection Dyeing) ensures absolute repeatability, productivity, and reliability for multicolor printing and dyeing of yarn in bobbins. Nautilus is a cutting-edge machine. Conceived with a double belt, it is suitable for dyeing delicate fabrics keeping the low liquor ratio constant by the maximum fabric load up to 40%. Low water consumption means low electrical consumption and energy saving. 250 HT Jet, is the easy machine that never stops getting perfectly dyed fabrics with no abrasions or creases.

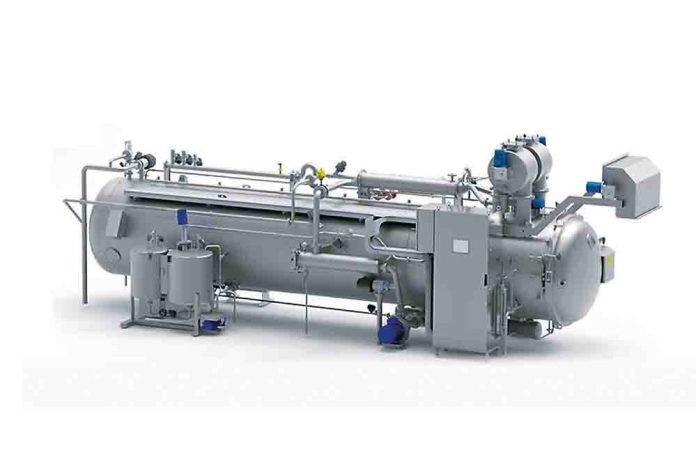

Beam, the ideal machine to dye high-end silk and technical fabrics, tubular and warp knit for sportswear enabling the optimisation of production times and superlative technical performance.

One constant is to be able to make machines that can prove effective in all-around energy savings, not an easy task in the dyeing sector, LAIP, as always, meets the challenge and the results are manifest. Less water consumption, more efficient components, more automation, and indeed, significant energy savings.