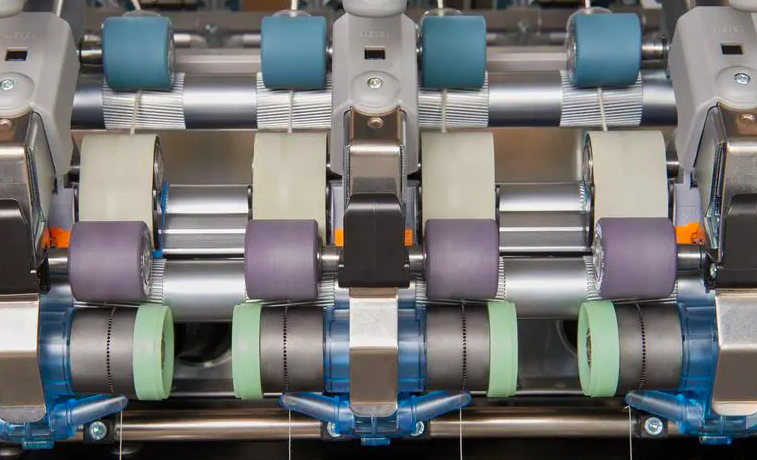

Compact spinning produces superior ring yarns, which offer special advantages in downstream processing. However, minimal hairiness with maximum compaction is something the spinners look for. Rieter’s compacting device COMPACTdrum for the ring spinning machine allows quick switches between ring yarn and compact yarn. COMPACTdrum adds a new dimension to reducing hairiness. Compact yarn produced in this way is highly sought-after in downstream processing. The device processes all raw materials and covers all yarn counts. With low energy requirements, very high productivity, and long-life technology components, production costs are kept low by COMPACTdrum.

The machine offers various advantages including:

Economy: COMPACTdrum allows compact yarns to be spun with very low production costs thanks to the low energy requirements – even with the highest productivity levels. The sieve drum system is low-maintenance as it is fitted with components that have a long service life. This ensures that maintenance costs are kept to a minimum.

Quality: A new dimension in hairiness reduction: COMPACTdrum reduces long hairs to an absolute minimum. Compact yarn produced this way is highly demanded in downstream processing, and the compacting device produces yarns with even better properties than other compact yarns. The long-life technology components of the COMPACTdrum ensure that the yarns produced are constantly high quality over a long period.

Flexibility: The compact device is easy to install and remove, offering high levels of flexibility when faced with market requirements that are constantly changing. COMPACTdrum offers a high level of flexibility, and it processes every type of fiber and can be adjusted to suit each raw material easily and quickly. New Rieter ring spinning machines can be delivered with COMPACTdrum, and existing Rieter machines can be upgraded.

Rieter is the world’s leading supplier of systems for manufacturing yarn from staple fibers in spinning mills. Based in Winterthur (Switzerland), the company develops and manufactures machinery, systems, and components used to convert natural and man-made fibers and their blends into yarns cost-efficiently.