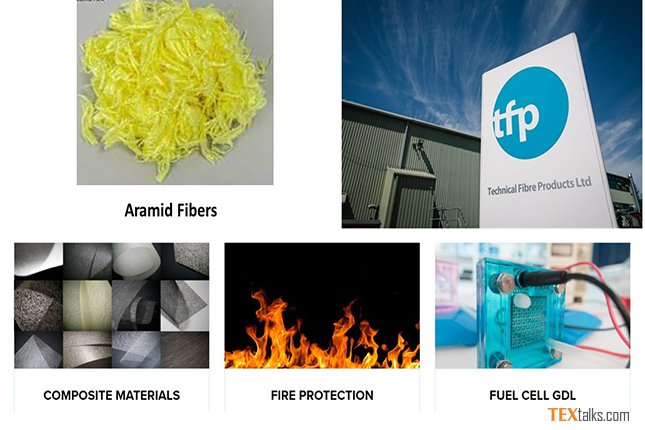

Technical Fibre Products (TFP) is now using aramid fibers for a wide range of applications, including abrasion resistance, conductivity or EMI shielding (using metal-coated veils), corrosion resistance (glass or carbon), and even fire protection (with Tecnofire). The TFP is a UK-based company known as a leading global manufacturer of wet-laid nonwovens. Our advanced materials provide solutions for challenging applications in aerospace, defense, fuel cells, composites, automotive, construction, and much more.

According to TFP, their latest study examined the effectiveness of surfacing veils to increase the wear resistance of composite panels both with and without TFP’s aramid veils.

The study examined the effectiveness of using a surfacing veil to increase wear resistance by comparing composite panels fabricated with and without TFP’s aramid veils. The panels (based on epoxy resin and woven carbon) were tested using a pin-on-disk tribometer to measure friction and wear as a function of time.

The data generated demonstrated that the measured coefficient of friction was significantly lower when an aramid surfacing veil was used, taking at least five times as long to reach the level measured in control.

The findings demonstrate the importance of the aramid veil in acting as a sacrificial layer to protect the underlying reinforcement, ultimately increasing the durability of the composite structure and extending its lifespan.

TFP said, “Our lightweight aramid veils enable a high-quality surface finish while simultaneously providing a durable and sacrificial layer in applications such as high-speed composite rollers, automotive friction substrates, or sporting goods where the composite experiences constant friction. This continuous wear can potentially have a detrimental impact on the performance of the composite and significantly reduce the product’s lifespan.

Our nonwovens are also widely used as surfacing veils.

They have been designed for this function to ensure uniform resin uptake, eliminate dry spots, minimize print through and fiber breakout, and ultimately deliver a high-quality surface finish.”