Valérius 360 wanted to make a sustainable, circular approach possible in the fashion industry. But it needed a partner with the power to make this green dream a reality. Working together with Trützschler, a pioneering collaborative project has now achieved high-quality recycled yarn – opening up the massive potential to drive measurable progress toward a circular and sustainable textile industry.

Valérius 360 was founded in Portugal in 2017. It produces yarn by recycling waste from its own spinning and knitting processes – which keeps more material in the economic cycle for longer, cutting down waste and making an important contribution to sustainability. Recently, its experts launched a new project with the ambitious aim of increasing the quality of yarn made from recycled waste fiber. But processing recycled fibers is tricky in many ways. Reopening textiles down to the fiber, for example, leads to a reduction in fiber quality.

Trützschler has innovative technologies and significant experience that support spinners with applications that involve recycled waste fibers. Our experts have a deep understanding of the decisive role that fiber and spinning preparation stages play in the quality of the final yarn. In partnership with Valérius 360, we explored the possibilities to make their project a success.

Testing at the Trützschler Technical Center

The team from Valérius 360 wanted to find ways of improving the processes for yarns made from 50 % recycled and 50 % virgin cotton (Ne30). In particular, it was seeking ways to reduce thick and thin spots, which disturb the appearance of the textile surface.

At the Trützschler Technical Center in Mönchengladbach, we conducted special trials that showed that using a direct spinning process for this application delivers much better results than a process with a draw frame passage for rotor yarns.

In direct spinning, the sliver from the card is directly drawn in the draw frame which is integrated into the can stock (see figure 1, test 2). This involves one less process step than using an autoleveller draw frame (see figure 1, test 2), while also saving space and giving staff more time for other operations.

Energy efficiency and cost savings

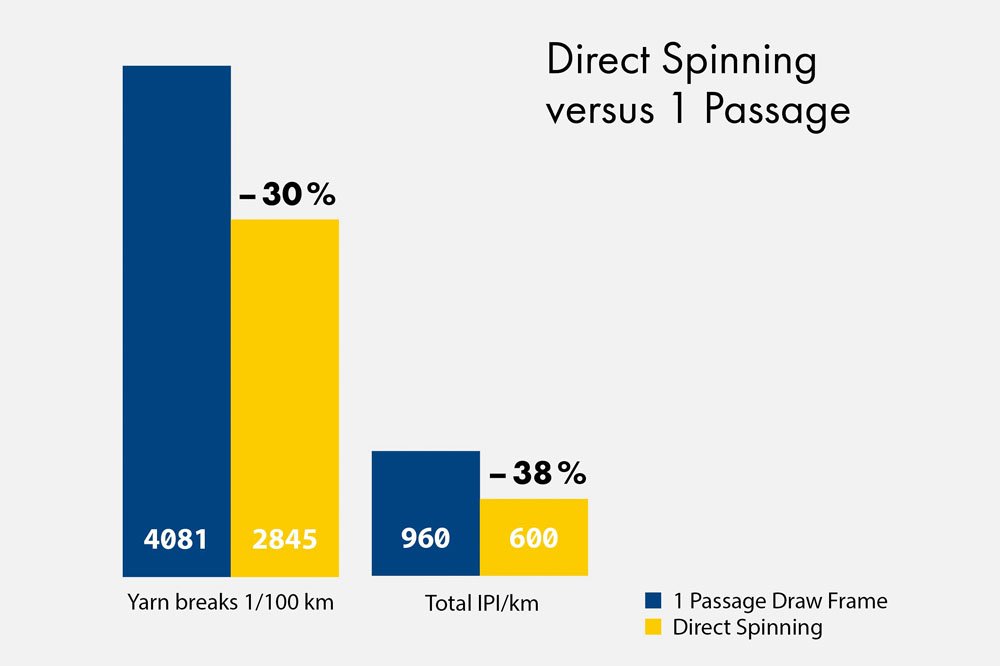

Direct spinning showed a clear capacity to reduce the number of faults in the yarn. As a result, the yarn breaks were 30 % lower and the Total IPI 38 % lower (see figure 2). The direct spinning process also has a positive effect on energy consumption: Compared to the process with a draw frame passage, for medium plant size, a savings potential of 5 % is achieved with direct spinning. At an energy price of 0.2 €/kW, the savings amount to over 5,000 € per year.

On-site support from Trützschler Customer Service

The team from Valérius 360 also received in-house training from the Trützschler Customer Service department. Together, they analyzed and significantly improved the process at the Valérius 360 production site. This helped to bring yarns made from recycled raw materials up to the required level of 50% Usterstatistics. This is the reference level for yarns made from virgin raw materials. Accordingly, 50 % of all yarn producers with raw cotton for rotor yarns and comparable yarn counts produce a poorer quality.

Trützschler is deeply committed to supporting its customers on the journey to a more sustainable textile industry. This case study shows how customers can improve the processing of recycled materials by using preparation systems from Trützschler. This includes plant concepts for fiber preparation, such as T-Blend or the TC 19iR. It also includes concepts for spinning preparation like direct spinning with the unique IDF from Trützschler. These innovative systems help customers to maximize the full potential of the material they are processing – because quality is decided in the preparation stage!

“We believe that right now the fashion industry is in a position to actively play a pioneering role in restoring the environment and thus restoring humanity, and we want to make our contribution to that,” said Patrícia Ferreira, CEO of Valérius Hub. “We are very grateful for the great support that Trützschler has given and continues to give us at all levels – from machine configuration through to product development, assembly, and customer service”, adds Miklós Pál Nagy, Manager at Valérius 360.