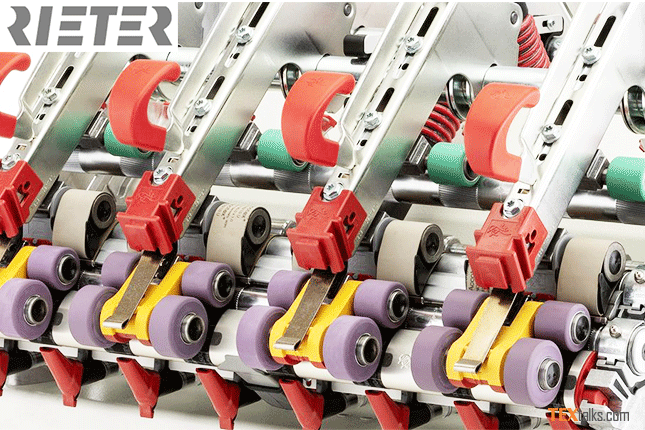

EliTe®Compact Spinning System processes effectively carded and combed cotton, man-made fibers and their blends. The pneumatic system arranges the fibers in a completely parallel and close position before twist is imparted and embeds all fibers and fiber ends into the yarn body, the air flow condenses the drafted fiber. This eliminates the spinning triangle.

Benefit in the spinning process

-Increased yarn strength and work capacity

-Reduced hairiness values and improved IPI imperfection values

-Increase in production due to reduced yarn twist and higher spindle speed

-Reduced ends-down rate and fiber loss

-Substantially improved spinning stability

Main benefits in the downstream processes

-Less machine contamination

-Increased production in weaving and knitting

-Reduced ends-down rate in warp and weft

-Reduced twist insertion into plied yarn

-Saving in sizing agent, singeing can be dispensed with in many cases

-Reduced abrasion, improved pilling behavior

-Substitute for plied yarns

-Improved hand and lustre in the final product

ELITE®COMPACT IN WORSTED SPINNING

-Increased yarn strength and elongation and reduced ends-down rate

-Improved yarn evenness and imperfection values IPI

-Reduced yarn hairiness values

-Less twist insertion required

Benefit in all Downstream Processes

-Less machine contamination

-Production increase and machine efficiency in weaving and knitting

-Less twist insertion into plied yarn

-Lower ends-down rate in warp and weft

-In many cases waxing can be dispensed with

-Cone dyeing instead of top dyeing

-Better hand and lustre in the final product

Two-Ply Compact Yarn directly from your Ring Spinning Machine

EliTwist® combines compact spinning and twisting of a yarn in one single operation and can be fitted to all spindles of EliTe®.

The specific yarn structure provides for the typical characteristics of EliTwist®Yarns, which are responsible for the very good processing properties.

EliTwist® is the most cost-effective method worldwide to produce two-ply compact yarns. The technological yarn parameters are unequaled. The EliTwist®System can be retrofitted to all EliTe®Spindles so far delivered. All ring spinning machines suitable for the EliTe®CompactSet can be equipped with EliTwist®.