Rajaguru Spinning Mills Private Limited operates over 130 000 ring spindles and produces over 30 000 tons of viscose ring yarn per year. Now the management decided to venture into air-jet technology. Rajaguru Spinning Mills chose Rieter’s air-jet spinning machine J 26 after taking references of several installations in other countries into account. Today the company produces high-quality Com4®jet yarns at a production efficiency of up to 98% with the best downstream performance and zero interruptions during weaving and knitting.

The Challenge: High quality air-jet yarn with best downstream performance

The company produces over 30 000 metric tons of viscose ring yarn per year. The management wanted to venture into air-jet spinning technology to produce high-quality yarns with the best downstream performance and zero interruptions during weaving and knitting.

The Solution: Air-jet spinning machine J 26

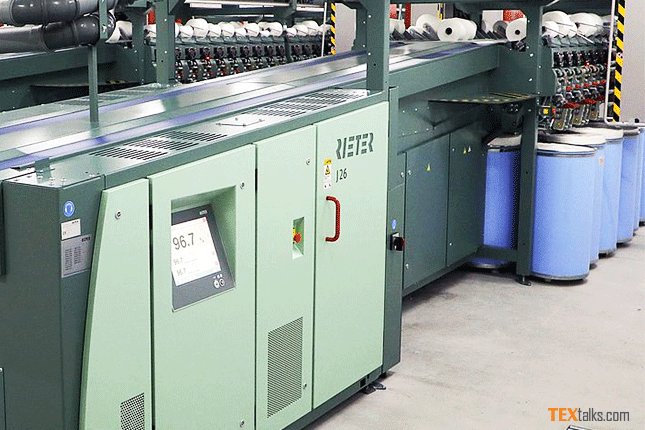

Rajaguru knows that Rieter is the only system supplier that has the state-of-the-art technology machines for producing all four types of yarns. Due to its unique yarn forming technology, the air-jet spinning machine J 26 from Rieter was the company’s first choice. Taking references of several installations in other countries into account, Rajaguru’s confidence in the J 26 was strengthened thanks to the high productivity, the yarn quality and the low conversion costs of the machine. Subsequently the company ordered four J 26 with 120 spinning positions each and five draw frames.

The Customers’s Benefits

Rajaguru now produces high-quality Com4®jet yarns at a production efficiency of up to 98%. The yarn is well established and accepted by the customers in both domestic and export markets. Rajaguru has now created its own brand in the market with the uniform fabric structure of air-jet yarns. The unique benefits for the company are:

– The productivity is 5% higher than originally committed by Rieter during order confirmation.

– Com4®jet yarns stand for consistent quality with lower yarn imperfections and lower yarn hairiness.

-Yarn-like piecing results in downstream process without stops and a fabric with a high evenness.

– Each spinning position consumes 5% less electrical power and 10% less pneumatic air per kilogram of produced yarn compared to air-jet spinning machines of competitors.

– With the possibility to produce two different lots per machine, the company responds quickly and flexibly to the dynamic market needs.