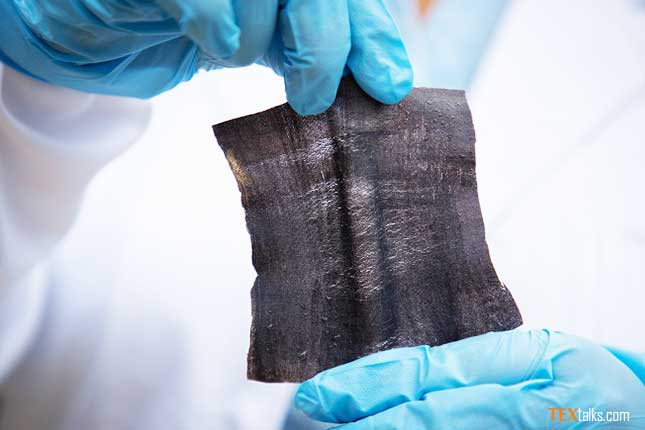

The next generation of waterproof smart fabrics can be laser printed and made in minutes. Scientists from RMIT University have developed a cost-efficient and scale-able method for rapidly fabricating textiles that are embedded with energy storage devices. In just three minutes, the method can produce a 10x10cm smart textile patch that’s waterproof, stretchable and readily integrated with energy harvesting technologies.

The technology enables graphene super-capacitors – powerful and long-lasting energy storage devices that are easily combined with solar or other sources of power – to be laser printed directly onto textiles, the scientists explain.

In a proof-of-concept, the researchers connected the super-capacitor with a solar cell, delivering an efficient, washable and self-powering smart fabric that overcomes the key drawbacks of existing e-textile energy storage technologies.

The growing smart fabrics industry has diverse applications in wearable devices for the consumer, health care and defence sectors – from monitoring vital signs of patients, to tracking the location and health status of soldiers in the field, and monitoring pilots or drivers for fatigue.

Robust and reliable

Dr Litty Thekkakara, a researcher in RMIT’s School of Science said that smart textiles with built-in sensing, wireless communication or health monitoring technology called for robust and reliable energy solutions.

Dr Thekkakara said, “Current approaches to smart textile energy storage, like stitching batteries into garments or using e-fibers, can be cumbersome and heavy, and can also have capacity issues. These electronic components can also suffer short-circuits and mechanical failure when they come into contact with sweat or with moisture from the environment. Our graphene-based super-capacitor is not only fully washable, it can store the energy needed to power an intelligent garment – and it can be made in minute’s at large scale. By solving the energy storage-related challenges of e-textiles, we hope to power the next generation of wearable technology and intelligent clothing.”

Possibilities

The research analyzed the performance of the proof-of-concept smart textile across a range of mechanical, temperature and wash-ability tests and found it remained stable and efficient.

Mr Min Gu, RMIT Honorary Professor and Distinguished Professor at the University of Shanghai for Science and Technology said, “The technology could enable real-time storage of renewable energies for e-textiles: It also opens the possibility for faster roll-to-roll fabrication, with the use of advanced laser printing based on multifocal fabrication and machine learning techniques.”