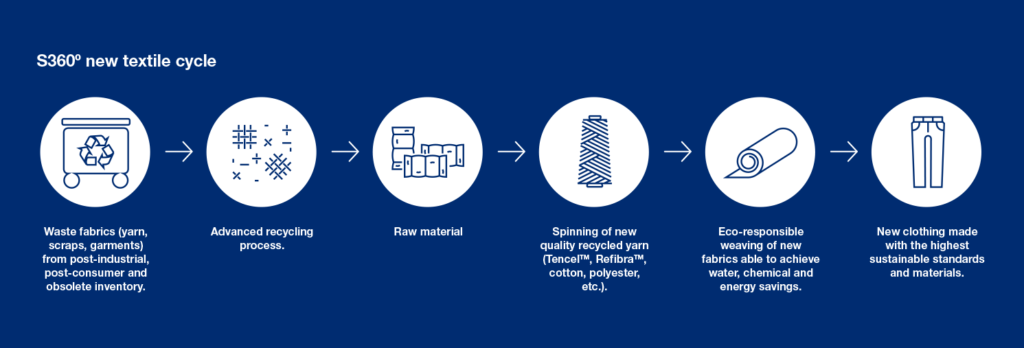

S360o is an innovative, sustainable circular cycle that gives fabrics a brand-new life. Spain-based mill Textil Santanderina is closing the loop with its S360 production process. The solution takes pre-and post-consumer waste and upcycles it into new textiles. At a recycling plant in Morocco, the fabric first goes through stripping machines that separate the scraps into smaller pieces, and then the fibers are carded to clean and combine before spinning. The mill saves on water, chemicals, and energy by repurposing scraps and deadstock.

The textile waste is processed with stripping machines that break the yarns and fabric into smaller pieces during the recycling process before pulling them apart into a fiber. The mix is carded several times to clean and mix the fibers before being spun into new yarns and textiles. Textil Santanderina is a cutting-edge company located in Cantabria and one of the textile benchmarks for quality and service.

The company is customer-focused and has an extensive product range that includes everything from cotton classics to the latest innovations using technical fibers.

This article has been taken from the talk of Laetitia Grimoult, export manager at Textil Santanderina, who spoke with Carved in Blue about her company’s start in circularity and how TENCEL™ lyocell fibers fit into the recycled fabrics.