The need for quality and price advantages is unbroken in textile finishing. New materials and pression from the fashion industry for sustainable textiles require manufacturing tools to produce with less energy, a lower carbon footprint and less chemicals and water. The SETEX manufacturing management software OrgaTEX makes an extremely important contribution to maintaining business operations under such difficult conditions.

The power of connection

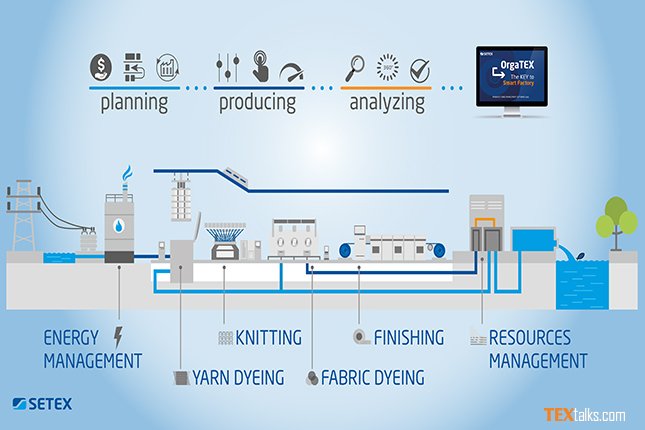

To deliver the benefits, OrgaTEX offers a suite of product features that provide a constant data stream from master data to color management laboratory, color kitchen and production machines.

With the merging of master data and operational technology, SETEX provides integration with state-of-the-art connectivity. Enabling self-adapting OrgaTEX production processes to control and override production machines and systems, allows for closed-loop energy management.

this month with approximately 2.7 million hectares projected to be planted with cotton this season, similar to 2012/13. However, higher yields are expected to result in an increase in South American production. Since smaller companies in particular have only small budgets, individual developments as well as the adaptation of expensive standard software are usually excluded.

The OrgaTEX ecosystem offers configurable automation, where processes can be continuously added and upgraded.

In combination: people, processes and technologies

Mastering and reducing complexity is a prerequisite for successful process optimization. The new generation OrgaTEX module “smart recipe” simplifies and speeds up the daily business bulking workflow. Standard procedures contain process details for all possible production variants.

An intelligent algorithm only uses exactly those chemicals, treatments and process steps, that are required for the optimal production of every unique order. To learn from production behavior, the digitalized transfer of knowledge happens from the minds of the employees into the formal structures of the Formula Wizard application.

Predictive Maintenance Services

Machine downtime costs and penalties for late deliveries have an impact on the equipment effectiveness (OEE). The OrgaTEX Maintenance Manager predicts, when is the best time to schedule maintenance. To do so, various counters in every machine talk to an OrgaTEX instance with machine components and their maintenance rules. The connection with a spare parts management orders the right parts, just before you need them.

In practice, the software schedules, controls and reports all maintenance and servicing works.

The OrgaTEX Maintenance Manager turns maintenance from a cost to value creation factor.

Intelligent Control Technology

Intelligent Control Technology

The brand new SETEX 390 controller generation is designed as industrial internet device (IIOT). Customers can use their PC, tablet or smartphone as a remote client without additional software installation. Machine-specific functions with split screens for video monitoring and picture-in-picture technology simplify the daily business drastically.

A new formula engine determines beside times, consumptions and events, the estimated batch consumptions for steam, water and other resources. The SETEX production organization software OrgaTEX and seamless integration of 3rd-party systems prepare the ground for the intelligent, efficient production and Industry 4.0 possibilities.