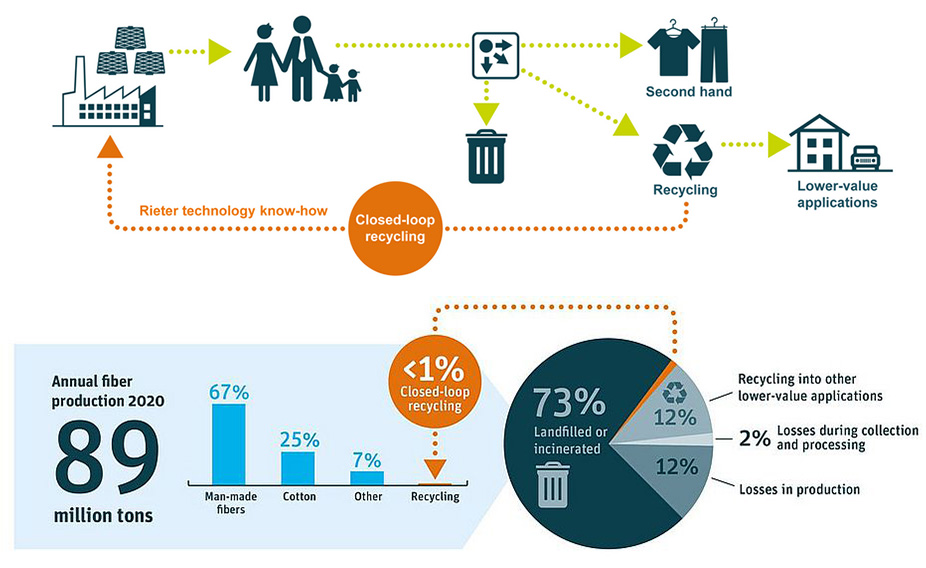

Driven by the vision of closing the textile loop, the partners of the “Texcircle” project successfully developed several such product prototypes following an intensive two-year period of research and development. As part of the team, Rieter contributed its in-depth recycling know-how. With barely 1% of garments being recycled and three-quarters of the world’s clothing ending up in landfill, the textile industry is actively seeking ways to make production patterns more sustainable and pay more attention to the entire life cycle of items of clothing.

Driven by the vision of closing the textile loop, the partners of the “Texcircle” project successfully developed several such product prototypes following an intensive two-year period of research and development. As part of the team, Rieter contributed its in-depth recycling know-how. With barely 1% of garments being recycled and three-quarters of the world’s clothing ending up in landfill, the textile industry is actively seeking ways to make production patterns more sustainable and pay more attention to the entire life cycle of items of clothing.

Rieter is actively committed to a sustainable policy, using its technological expertise to offer a complete recycling spinning system for both ring and rotor spinning lines that enables customers to spin fibers from used garments and waste into yarns.

Rieter is the world’s leading supplier of systems for manufacturing yarn from staple fibers in spinning mills. Based in Winterthur (Switzerland), the company develops and manufactures machinery, systems, and components to convert natural and man-made fibers and their blends into yarns cost-efficiently. Cutting-edge spinning technology from Rieter contributes to sustainability in the textile value chain by minimizing the use of resources. Rieter has been in business for over 225 years, has 18 production locations in ten countries, and employs a global workforce of around 5 590, about 16.4% of whom are based in Switzerland.

Rieter’s Rotor Spinning Recycling

Rieter has optimized the rotor spinning technology, which is naturally adapted for applications using materials with short fibers, and special geometries and options allow for optimized adaptations. The fully automated machine combines the high potential for yarn tenacity with the capability to handle many ends with excellent piecing quality. As a result, using Rieter’s recycling system on a rotor spinning line makes it possible, for example, to spin yarn up to Ne 20 with a blend of 75% post-consumer material and 25% virgin cotton or yarn up to Ne 30 with a blend of 87,5% pre-consumer material and polyester.

Rieter’s Rotor Spinning Recycling

Rieter offers a complete system designed to process short fibers in the best possible way. Despite the presence of very short fibers from the recycled post-consumer branch, the yarns obtained can be used in weaving and knitting applications. Rieter’s recycling system makes it possible, for example, to spin ring yarn up to Ne 20 with a blend of 60% post-consumer material and 40% virgin cotton or yarn up to Ne 30 with a blend of 60% pre-consumer material and 40% polyester.